Main page

About us

Sliding Bearings Consulting

Advertising Opportunities

to Ceramics

Methods of shape forming ceramic powders

Dr. Dmitri Kopeliovich

Prior to shape forming ceramic powders are mixed with processing additives (binders, plasticizers, lubricants, deflocculants, water etc.).

Powder preparation stage is followed by shape forming stage.

The following techniques are involved in forming ceramic powders into a desired shape:

Uniaxial (Die) Pressing

Die pressing is the powder compaction method involving uniaxial pressure applied to the powder placed in a die between two rigid punches.

Uniaxial (die) pressing is effectively used for mass production of simple parts (alternative method is isostatical pressing).

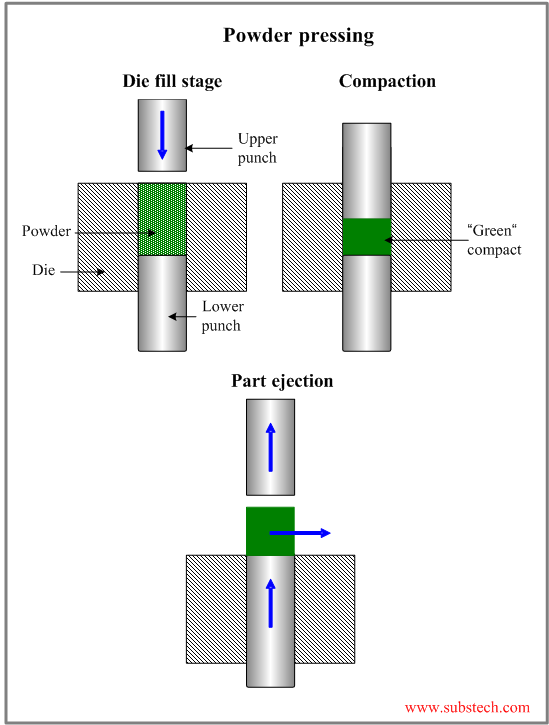

The scheme of the die pressing method is presented in the picture:

The pressing process consists of the following stages:

- Die filling

At this stage a controlled amount of the powder is fed into the die cavity.

- Compaction

Upper punch moves down and presses the powder with a predetermined pressure. The pressure varies between 10,000 psi to 120,000 psi (69 MPa to 830 MPa).

- “Green” compact part ejection and removal (“green” compact – unsintered powder compact) .

The pressing cycle repeats 400 to 5000 times/hour, depending on the press type, powder filling properties and the part size and geometry.

Hydraulic and mechanical presses with load up to 750 tons are used for the powder die pressing.

Die pressing, which is conducted at thr room temperature is called cold pressing.

If the pressing process is conducted at increased temperature it is called hot pressing.

For example hot pressing of silicon carbide is carried out at temperature about 3630 ºF (2000ºC).

Hot pressing permits obtaining better compaction, higher green compact density and higher (than in cold pressing) strength of the part.

Die pressing is used for manufacturing insulating parts, magnetic ceramics, capacitors, substrates.

to top

Isostatic Pressing

Isostatic pressing is the powder compaction method involving applying pressure from multiple directions through a liquid or gaseous medium surrounding the compacted part.

Cold isostatic pressing (CIP) is conducted at room temperature.

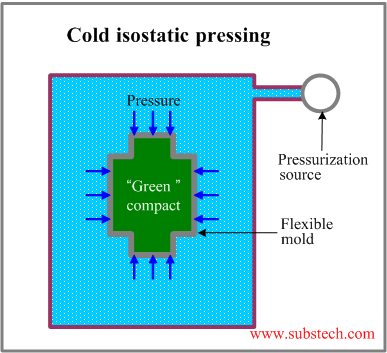

A flexible (commonly polyurethane) mold immersed in a pressurized liquid medium (commonly water) is used in the cold isostatic pressing method (see the scheme below):

There are two types of cold isostatic pressing: wet bag and dry bag.

In the wet bag method the mold is removed and refilled after each pressure cycle. This method is suitable for compaction of large and complicated parts.

In the dry bag method the mold is an integral part of the vessel. The dry bag method is used for compaction of simpler and smaller parts.

The cold isostatic pressing (CIP) method has the following advantages as compared to the die cold pressing method:

- better uniformity of compaction;

- more complex forms (for example long thin-walled tubes) may be compacted;

Hot isostatic pressing (HIP) involves isostatic pressing conducted at increased temperature.

As a pressure medium a gas (Nitrogen or Argon) is used.

The work pressures, which are applied in the hot isostatic pressing method, are commonly between 15,000 psi to 44,000 psi (100 MPa to 300 MPa).

Hot isostatic method (HIP) combines pressing and sintering, causing consolidation of powder particles, healing voids and pores. The part shrinks and densifies, forming sound high strength structure.

Cans made of stainless steel, or mild steel are used in the method.

The method may be used without a mold. In this case the part is first compacted by cold isostatic pressing method, and then it is sintered in order to close the interconnecting porosity. The sintered (but still porous) part is then pressed isostatically at high temperature without any can (mold).

to top

Injection Molding

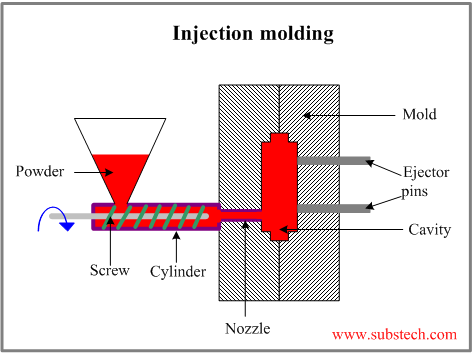

Injection moldingis the method of compaction of ceramic powder fed and injected into a mold cavity by means of a screw rotating in cylinder.

The method is similar to the plastic injection molding.

The principal scheme of the injection molding method is shown in the picture:

The processing technology comprises the following stages:

- Mixing the ceramic powder with 30% - 40% of a binder – low melt polymer.

- Injection of the warm powder with molten binder into the mold by means of the screw.

- Removal of the part from the mold after cooling down of the mixture.

- Debinding – removal of the binder. There are two debinding methods:

- solvent debinding – the binder is dissolved by a solvent or by water;

- thermal debinding – the binder is heated above the volatilization temperature.

- Sintering the “green” compact.

Injection molding method is widely used for manufacturing small parts having complex shapes.

The molding cycle in the injection molding method is about 10 sec, which much less, than the molding time in the alternative methods – 10-20 min.

The method permits to produce part with close tolerance, due to the consistent shrinkage. This shrinkage is taken into account in the mold design.

to top

Extrusion

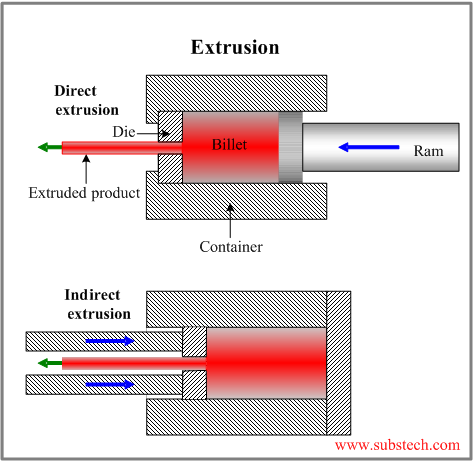

The two possible schemes of extrusion are presented in the picture:

Extrusion ram forces the ceramic paste through a die, resulting in a long product (rods, bars, long plates, pipes) of regular cross-section, which may be cut into pieces of required length.

Extrusion is used for manufacturing furnace tubes, thermocouple components, heat exchanger tubes.

to top

Slip Casting

Slip casting technique is used for shape forming ceramic slurry - a stable suspension, consisting of ceramic powders, processing additives and 20-35% of liquid (water or solvent).

The slurry is poured into a mold made of a micro-porous material (e.g. gypsum), which is capable to soak the liquid from the slurry, consolidating the ceramic part.

Slip casting is used for manufacturing fine china, sinks, sanitary ware, thermal insulation parts.

to top

Gel Casting

Gel Casting is a process of shape forming slurry prepared from ceramic powder mixed with a solution of organic monomer.

When the slurry is poured into a mold, the monomer polymerizes, forming a gel that binds ceramic powder particles into a strong complex-shaped part.

The parts may be machined before firing.

The process is economical and it is used for manufacturing large complex shapes parts such as turbine rotors.

to top

Tape Casting

Tape Casting is a process of forming a thin film of ceramic slurry spread over a flat surface.

The slurry film thickness is controlled by a knife edge located above the moving carrier surface.

The solvent, containing in the slurry, evaporates, resulting in formation of ceramic sheet, which may be stripped from the supporting surface.

Tape Casting is used for manufacturing multilayer ceramics for capacitors and dielectric insulators.

to top

Related internal links