to Polymers

Shore (Durometer) hardness test

Dr. Dmitri Kopeliovich

Shore hardness is a measure of the resistance of a material to penetration of a spring loaded needle-like indenter.

Hardness of Polymers (rubbers, plastics) is usually measured by Shore scales.

Shore A scale is used for testing soft Elastomers (rubbers) and other soft polymers.

Hardness of hard elastomers and most other polymer materials (Thermoplastics, Thermosets) is measured by Shore D scale.

Shore hardness is tested with an instrument called Durometer.

Durometer utilizes an indenter loaded by a calibrated spring.

The measured hardness is determined by the penetration depth of the indenter under the load.

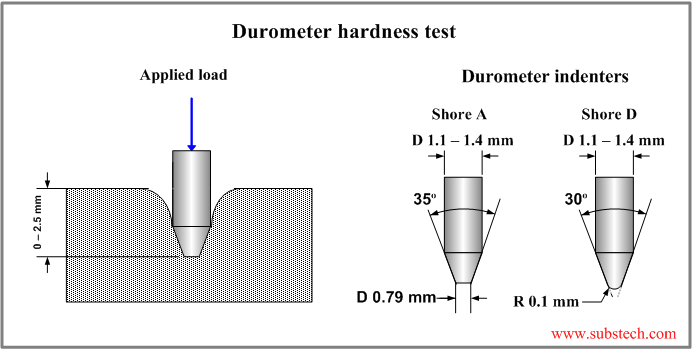

Two different indenter shapes (see the picture below) and two different spring loads are used for two Shore scales (A and D). The loading forces of Shore A: 1.812 lb (822 g), Shore D: 10 lb (4536 g).

Shore hardness value may vary in the range from 0 to 100. Maximum penetration for each scale is 0.097-0.1 inch (2.5-2.54 mm). This value corresponds to minimum Shore hardness: 0. Maximum hardness value 100 corresponds to zero penetration.

Durometer hardness conversion

| Shore A | 30 | 35 | 40 | 45 | 50 | 55 | 60 | 65 | 70 | 75 | 80 | 85 | 90 | 95 | 100 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Shore D | 6 | 7 | 8 | 10 | 12 | 14 | 16 | 19 | 22 | 25 | 29 | 33 | 39 | 46 | 58 | |

Rubber hardness and applications

| Hardness | Application |

|---|---|

| 30 Shore A | Art gum erasers |

| 35 Shore A | Rubber bands |

| 40 Shore A | Can tester pads |

| 50 Shore A | Rubber stamps |

| 55 Shore A | Pencil erasers |

| 60 Shore A | Screen wiper blades |

| 65 Shore A | Automotive tires |

| 70 Shore A | Shoe heels |

| 75 Shore A | Abrasive handling pads |

| 80 Shore A | Shoe soles |

| 85 Shore A | Tap washers |

| 90 Shore A | Typewriter rollers |

| 95 Shore A | Fork lift solid tires |

| 60 Shore D | Golf ball |

| 70 Shore D | Metal forming wiper dies |

| 80 Shore D | Paper-making rolls |

Related internal links

to Polymers