Main page

About us

Sliding Bearings Consulting

Advertising Opportunities

to Ceramics

to Carbon materials

Graphite manufacturing process

Dr. Dmitri Kopeliovich

The process of synthetic graphite manufacturing consists of the following principal stages:

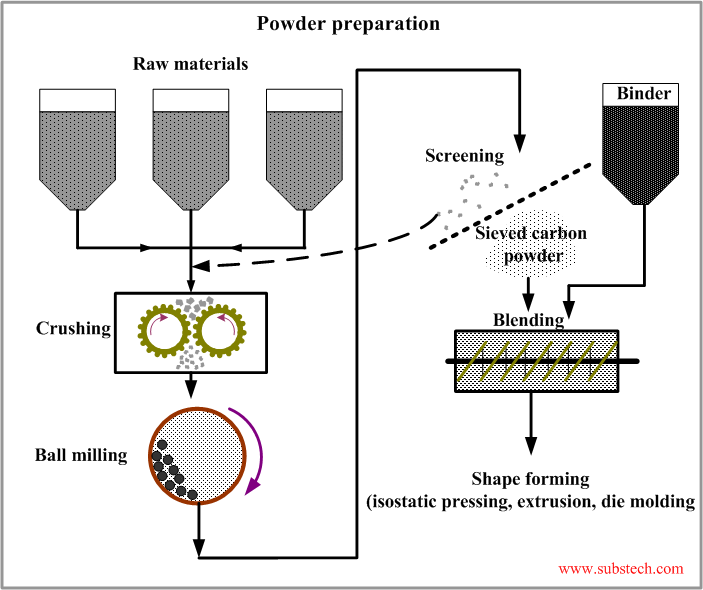

Powder preparation

Raw materials for synthetic graphite fabrication (petroleum coke, pitch coke, carbon black, natural graphite and secondary graphite scrap are loaded and stored in raw materials silos.

At the first step the raw materials are pulverized (ground) in crushers and ball mills.

The resulted powder is conditioned according to the particles size distribution (screening).

The last step of powder preparation process is blending the powder with a binder. Coal tar pitch, petroleum pitch or synthetic resins are used as binders.

The powder preparation process is presented in the scheme below.

to top

Shape forming

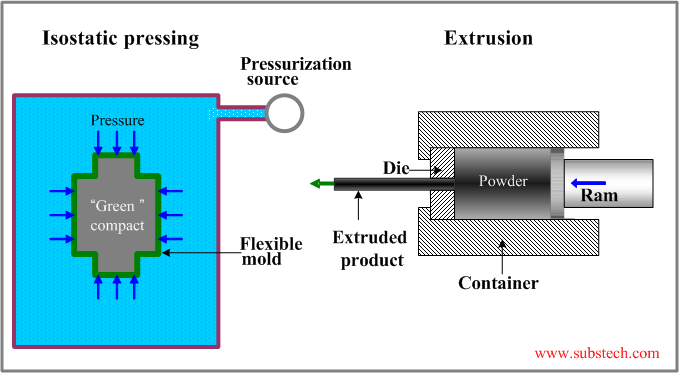

Carbon powder mixed with a binder may be compacted by one of the shape forming techniques: cold isostatic pressing, extrusion or die molding.

- Cold isostatic pressing

Cold isostatic pressing is the powder compaction method conducted at room temperature and involving applying pressure from multiple directions through a liquid medium surrounding the compacted part.

A flexible (commonly polyurethane) mold immersed in a pressurized liquid medium (commonly water) is used in the cold isostatic pressing method (see the scheme below):

Materials with uniform isotropic structure are prepared by isostatic pressing method.

- Extrusion

Extrusion is a shaping a powder mixture by forcing it through a die with an opening.

Extrusion results in a long product (rods, bars, long plates, pipes) of regular cross-section, which may be cut into pieces of required length.

Extruded graphite materials are anisotropic (properties in the extrusion direction differ from the properties in other directions).

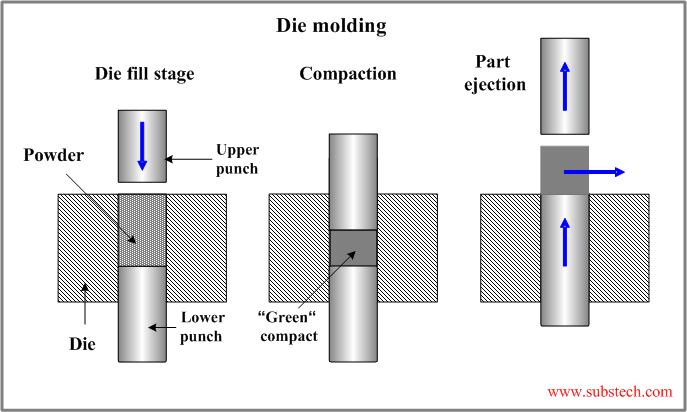

- Die molding

Die molding (pressing) is the powder compaction method involving uniaxial pressure applied to the powder placed in a die between two rigid punches.

Uniaxial die molding is effectively used for mass production of simple parts (alternative method is isostatical pressing).

The scheme of the die molding method is presented in the picture:

The die molding process consists of the following stages:

Die filling At this stage a controlled amount of the powder is fed into the die cavity.

Compaction Upper punch moves down and presses the powder at room or elevated temperature with a predetermined pressure. The pressure varies between 10,000 psi to 120,000 psi (69 MPa to 830 MPa).

“Green” compact part ejection and removal (“green” compact – shaped powder) .

The pressing cycle repeats 400 to 5000 times/hour, depending on the press type, powder filling properties and the part size and geometry. Hydraulic and mechanical presses with load up to 750 tons are used for the powder die pressing.

to top

Baking

The compacted parts (”green compacts”) are heat treated (baked) in a baking furnace at 1840-2200°F(1000-1200ºC) in the absence of air.

The baking process, which is called carbonization, results in thermal decomposition (pyrolysis) of the binder into elementary carbon and volatile components.

Carbon formed in the carbonization process binds the powder particles. The volume of the binder is higher than the volume of the formed carbon, therefore carbonization results in formation of pores, total relative volume of which (porosity) is determined by the binder quantity.

to top

Graphitization

At this stage the shaped and baked parts are heat treated under exclusion of Oxygen (air) at extremely high temperature 4530-5430°F (2500-3000°C).

The process, called graphitization, results in Crystallization of amorphous precursor carbon, which transforms into crystalline graphite. During this high temperature tratment graphite is also purified since most its impurities (binder residues, gases, oxides, sulfur) vaporize.

Graphitization furnaces utilize heat generated by either electric current passing through the graphitizing material or induction heating.

to top

Pyrolytic graphite

Pyrolytic graphite is a form of graphite produced by high temperature decomposition of hydrocarbon gases in vacuum followed by deposition of the carbon atoms to the substrate surface. The process is called Chemical Vapor Deposition (CVD).

The resulting material is ultra pure anisotropic graphite possessing near theoretical density (no pores), excellent thermal conductivity and high strength.

Pyrolytic graphite is used as a non-permeable coating on sintered graphite.

to top

Related internal links