Main page

About us

Sliding Bearings Consulting

Advertising Opportunities

to Metals

to Powder metallurgy

Powder preparation

Atomization

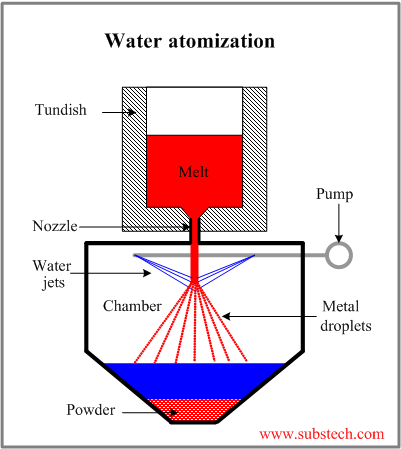

Atomization is one of the most effective industrial powder preparation methods.

This method involves desintagration (atomizing) of liquid metal by means of high speed medium (air, inert gas, water) striking the melt streaming through a nozzle.

- The molten alloy is prepared in a furnace and then it is transferred to the tundish.

- The melt is poured from the tundish through the nozzle into the chamber.

- The water (air, gas) jets break the melt stream into fine droplets.

- The droplets solidify when they fall in the chamber.

- The powder is collected at the bottom of the chamber.

- The powder is removed from the chamber and dried (if necessary).

Comminution

Comminution is a mechanical method of powder preparation involving breaking solid particles in mills (ball, vibratory, hummer).

This method is generally applied for the preparation of powders of brittle materials.

The most widely used communition machine is ball mill, utilizing the energy of steel steel balls, which move in a rotating drum and crush the metal pieces into fine particles.

Maximum grinding effect is achieved at optimal rotation speed of the mill (N).

N = 0.6-0.8*Ncr

Ncr may be determined from the expression:

Ncr = (g/2D)1/2/π (revolutions per second)

where:

g - acceleration due to gravity;

D - drum diameter.

If N>0.8*Ncr then the balls “stick” to the drum wall and no grinding ocurrs.

If N<0.6*Ncr then the balls roll without falling. The grinding effect in this case is low (only rubbing).

If N = 0.6-0.8*Ncr then the balls go up together with the rotating drum and then fall down and roll providing grinding by combined action of strike and rubbing.

to top

Chemical methods of powder preparation

Metal powders may be prepared by reduction of the metal oxides (carbides) followed by mechanical crushing or precipitation of metals from solution (hydrometallurgical method).

Powder may be also prepared by electrolytic deposition of a metal at the cathode followed by mechanical crushing of the deposited material. This method is used for fabrication of copper powders.

These methods are called chemical powder preparation methods.

to top

Powder characteristics

- Particle shape.

Particle may be spherical (gas atomization), irregularly shaped (water atomization), porous (reduced oxides), dendrite like (electrolytic deposition).

- Particle size.

- Size distribution (relative quantities of different size fractions).

- Apparent density – the mass of a unite volume of the powder, which was freely (without pressing or tapping) poured into the container.

Apparent density is a function of porosity of the particles, regularity of their shapes and variety of their sizes.

- Compressibility – degree to which the powder compacts as a function of the applied pressure.

- Flowability – ability of the powder to flow through a calibrated orifice.

Related internal links