to Metals

to Steel making

Ladle refining

-

- Recirculation Degassing (RH)

- Recirculation Degassing with oxygen top lance (RH-OB)

- Ladle Degassing (VD, Tank Degassing)

- Vacuum Oxygen Decarburization (VOD)

-

- Powder injection

- Cored wire injection

Vacuum ladle degassing

Methods of vacuum ladle degassing utilize the reaction of deoxidation by carbon dissolved in steel according to the equation:

[C] + [O] = {CO}

where:

[C] and [O] - carbon and oxygen dissolved in liquid steel; {CO} - gaseous carbon monoxide.

Vacuum treatment of molten steel decreases the partial pressure of CO, which results in shifting equilibrium of the reaction of carbon oxidation. Bubbles of carbon monoxide form in the liquid steel, float up and then they are removed by the vacuum system.

In addition to deoxidation vacuum treatment helps to remove Hydrogen dissolved in liquid steel. Hydrogen diffuses into the CO bubbles and the gas is then evacuated by the vacuum pump.

Movement of the molten steel caused by CO bubbles also results in refining the steel from non-metallic inclusions, which agglomerate, float up and are absorbed by the slag.

CO bubbles also favor the process of floating and removal of nitride inclusions and gaseous Nitrogen.

Steels refined in vacuum are characterized by homogeneous structure, low content of non-metallic inclusions and low gas porosity.

Vacuum degassing methods are used for manufacturing large steel ingots, rails, ball bearings and other high quality steels.

Vacuum ladle degassing methods:

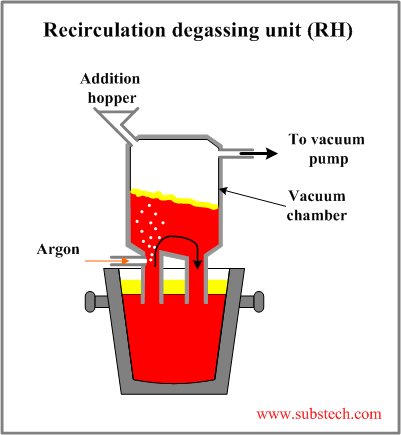

- Recirculation Degassing (RH)

Recirculation degassing unit uses a vacuum chamber having two snorkels connected to the chamber bottom. One of the snorkels is equipped with pipes supplying Argon through its refractory lining.

Recirculation degassing unit uses a vacuum chamber having two snorkels connected to the chamber bottom. One of the snorkels is equipped with pipes supplying Argon through its refractory lining.

The snorkels of the vacuum chamber are immersed into the ladle with molten steel. Liquid metal fills the chamber to a level determined by the atmospheric pressure (4.2ft/1.3m). Argon bubbles floating up in one of the snorkels (up-leg) force the melt to rise in the snorkel. Through the second snorkel (down-leg) the molten steel flows down back to the ladle producing circulation. The circulation rate may reach 150-200 t/min.

The recirculation degassing vacuum chambers are usually equipped with addition hoppers, through which alloying elements or/and desulfurization slag may be added.

Benefits of Recirculation Degassing (RH):

-Hydrogen removal (degassing);

-Oxygen removal (deoxidation);

-Carbon removal (decarburization);

-Sulfur removal (desulfurization);

-Precise alloying;

-Non-metallic inclusions removal;

-Temperature and chemical homogenizing.

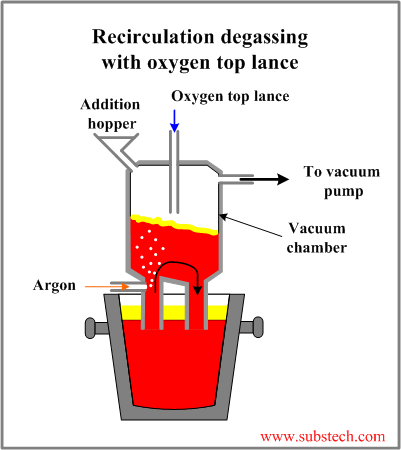

- Recirculation Degassing with oxygen top lance (RH-OB)

In this method a conventional Recirculation degassing (RH) vessel (chamber) is equipped with a vertical water cooled lance for blowing oxygen on the molten steel surface.

In this method a conventional Recirculation degassing (RH) vessel (chamber) is equipped with a vertical water cooled lance for blowing oxygen on the molten steel surface.

Oxygen intensifies the reaction [C] + [O] = {CO} resulting in fast and effective decarburization. Oxygen also oxidizes phosphorus like in Basic Oxygen Process (BOP) or in oxidizing slag stage in Electric-arc furnace.

Oxidation reactions have also heating effect therefore the treated metal may be heated to a required temperature without any additional energy source.

Benefits of Recirculation degassing with oxygen top lance (RH-OB):

-Hydrogen removal (degassing);

-Fast carbon removal (decarburization);

-Phosphorus removal (dephosporization);

-Sulfur removal (desulfurization);

-Reheating; -Precise alloying;

-Non-metallic inclusions removal;

-Temperature and chemical homogenizing.

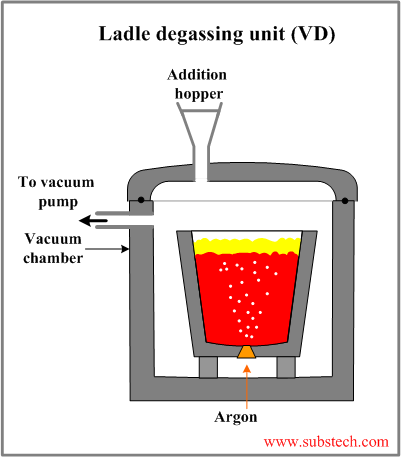

- Ladle Degassing (VD, Tank Degassing)

In the Tank Degassing method the ladle with molten steel is placed into a vacuum chamber. The ladle is equipped with a porous refractory plug mounted in the ladle bottom. Through the plug argon is supplied during vacuum treatment. There is an addition hopper with vacuum lock on the chamber cover. The hopper is used for adding alloying elements and/or slag components.

In the Tank Degassing method the ladle with molten steel is placed into a vacuum chamber. The ladle is equipped with a porous refractory plug mounted in the ladle bottom. Through the plug argon is supplied during vacuum treatment. There is an addition hopper with vacuum lock on the chamber cover. The hopper is used for adding alloying elements and/or slag components.

The reaction [C] + [O] = {CO} starting in the steel under vacuum conditions causes stirring, which is additionally intensified by argon blown through the bottom porous plug.

Intensive stirring of the melt and the slag results in deep desulfurization of the steel. Desulfurizing slags possessing high sulfur solubility are used in this process.

Argon and CO bubbles also favor the process of floating and removal of nitride inclusions and gaseous nitrogen.

Benefits of Ladle Degassing (VD, Tank Degassing):

-Hydrogen removal (degassing);

-Oxygen removal (deoxidation);

-Deep sulfur removal (desulfurization);

-Carbon removal (decarburization);

-Precise alloying;

-Non-metallic inclusions (oxides and nitrides) removal;

-Temperature and chemical homogenizing.

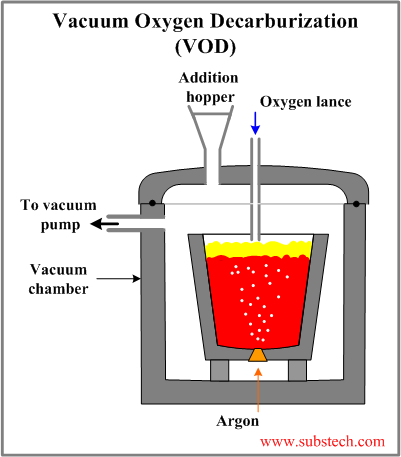

- Vacuum Oxygen Decarburization (VOD)

In this method a conventional Ladle Degassing (VD, Tank Degassing) chamber is equipped with a vertical water cooled lance for blowing oxygen on the molten steel surface.

In this method a conventional Ladle Degassing (VD, Tank Degassing) chamber is equipped with a vertical water cooled lance for blowing oxygen on the molten steel surface.

Vacuum Oxygen Decarburization (VOD) method is used for manufacturing Stainless steels. Oxidation of liquid steel components under vacuum differs from that at normal pressure: oxygen is consumed mainly by the reaction [C] + [O] = {CO} rather than by oxidation of chromium, which is the main constituent of stainless steels.

VOD process allows to decarburize the steel with minor chromium losses.

Oxidation reactions have also heating effect therefore the treated metal may be heated to a required temperature without any additional energy source.

After having the decarburization (oxidation) stage completed deoxidizers are added to the steel in order to remove excessive oxygen. Then a Desulfurizing slag is added to the molten steel surface. Stirring of the melt and the slag caused by argon blown through the porous bottom plug results in deep desulfurization of the steel.

Benefits of Vacuum Oxygen Decarburization (VOD):

-Deep carbon removal (decarburization);

-Low losses of chromium in treatment of stainless steels; -Hydrogen removal (degassing);

-Sulfur removal (desulfurization);

-Precise alloying;

-Reheating; -Non-metallic inclusions (oxides and nitrides) removal;

-Temperature and chemical homogenizing.

to top

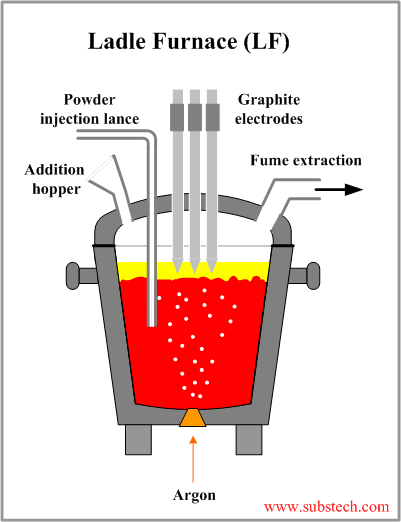

Ladle Furnace (LF)

Molten steel in a ladle may be treated (refined) in a device called Ladle Furnace (LF).

Molten steel in a ladle may be treated (refined) in a device called Ladle Furnace (LF).

The ladle is transported to the Ladle Furnace stand where it is placed under a cover equipped with three graphite electrodes connected to a three-phase arc transformer. The ladle bottom has a porous refractory plug, which is connected to the argon supply pipe at the Ladle Furnace stand. The LF stand is also equipped with an addition hopper mounted on the cover and a lance for injection of desulfurizing agents. Fumes formed during the operation are extracted through the cover.

Molten steel treated in Ladle Furnace is covered by a layer of desulfurizing slag. The graphite electrodes are submerged into the slag, which protects the ladle lining from overheating produced by the electric arcs. The arcs are capable to heat the steel at the rate about 5°F/min (3°C/min).

During the treatment process argon is blown through the bottom porous plug providing continuous metal stirring. Stirring results in distribution of heat produced by the arcs, chemical homogenization and desulfurization of the steel by the slag.

Alloying elements and/or slag components may be added through the addition hopper.

If deep desulfurization is required active desulfurizing agents are injected into the melt through the injection lance or in form of cored wire.

Besides refining operations Ladle Furnace (LF) may serve as a buffer station before Continuous casting.

Benefits of Ladle Furnace (LF):

- Deep sulfur removal (desulfurization);

- Controllable reheating by electric power;

- Alloying;

- Temperature and chemical homogenizing;

- Non-metallic inclusions removal.

Ladle Furnace process is used for refining a wide variety of steels, in which degassing (hydrogen removal) is not required.

to top

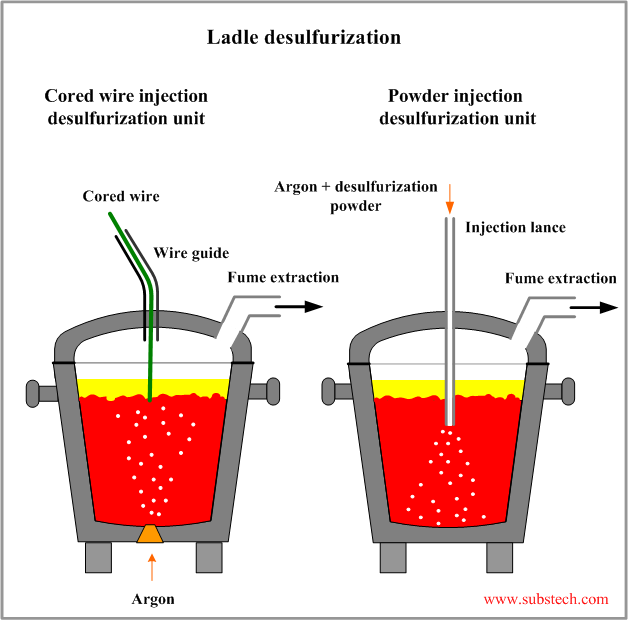

Ladle desulfurization by injection of active agents

Injection of desulfurizing agents (Ca, Mg, CaSi, CaC2, CaF2+CaO) to a molten steel is the most effective method of sulfur removal.

Injection methods usually combine supply of a disperse desulfurizing agent (powder) with stirring by argon blowing.

A ladle with deoxidized (killed) molten steel is transported to the injection stand where it is placed under a cover, through which the injection lance may lower and immerse into the melt.

Steel treated in the stand is covered by a layer of desulfurizing slag having high solubility of sulfur and capable to absorb sulfides formed as a result of active agents injection.

Desulfurization agents are injected in argon stream. Argon bubbles produce stirring of the molten steel and the slag promoting desulfurization. Stirring also provides thermal and chemical homogenization of the melt.

When the desulfurizing agents are injected into molten steel in form of a cored wire containing powder of desulfurizing agent stirring by argon bubbling from the porous plug mounted in the ladle bottom is used.

Fumes formed during the operation are extracted through the cover.

Injection of desulfurizing agents allows to achieve ultra-low concentrations of sulfur in steel (0.0002%).

Benefits of Ladle desulfurization by injection of active agents:

- Deep sulfur removal (desulfurization);

- Temperature and chemical homogenizing;

- Non-metallic inclusions removal.

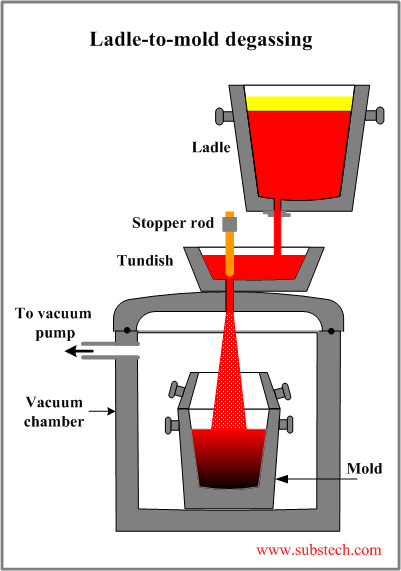

Ladle-to-mold degassing

Ladle-to-mold degassing is a vacuum degassing method, in which the mold is placed in a vacuum chamber.

Ladle-to-mold degassing is a vacuum degassing method, in which the mold is placed in a vacuum chamber.

The molten steel is poured from a tundish attached to the cover of the chamber.

The tundish is continuously filled with the melt poured from the ladle.

The steel stream “boils” when it is falling to the mold cavity in vacuum due to the deoxidation reaction [C] + [O] = {CO}.

Hydrogen dissolved in steel diffuses into the CO bubbles and the gas is then evacuated by the vacuum pump.

Intensity of the deoxidation and degassing during Ladle-to-mold pouring is indicated by the angle, at which the melt stream “opens” as a result of CO bubbles formation.

to top

Related internal links

to Metals

to Steel making