Main page

About us

Sliding Bearings Consulting

Advertising Opportunities

to Metals

to Foundry technologies

Continuous casting

Continuous casting is a casting method, in which the steps of pouring, solidification and withdrawal (extraction) of the casting from an open end mold are carried out continuously.

Cross-sectional dimensions of a continuous casting are constant along the casting length and they are determined only by the dimensions of the mold cavity.

The length of a continuous casting is limited by the life time of the mold.

Continuous casting technology is used for both ferrous and non-ferrous alloys.

Traditional continuous casting processes use stationary (or oscillating) molds, in which the solidified bar moves relative to the mold surface. Friction caused by the movement results in formation of micro-cracks and other defects in the surface regions of the casting. Lubricating oil supplied to the mold surface and self-lubricating graphite molds decrease the friction/sticking and reduce the defective surface zone. This defective zone is commonly machined (milled) prior to Rolling

The alternative continuous casting methods use moving “endless” molds (rolls, belts, wheels) characterized by zero relative movement between the mold and casting surfaces. Strips and slabs fabricated by Continuous casting in traveling mold have low defect surface. The castings may be further processed (rolled) without surface machining.

Depending on the mold position (vertical or horizontal) continuous casting machines may be vertical or horizontal:

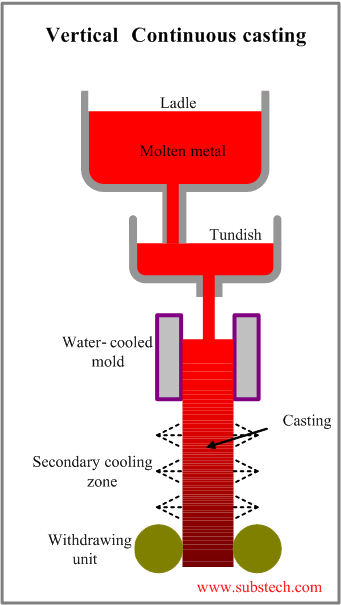

Vertical continuous casting

Steels are commonly cast in vertical continuous casting machines.

Molten metal is continuously supplied from the ladle to the intermediate ladle (tundish) from which it is continuously poured into the mold at a controllable rate keeping the melt level at a constant position.

The water-cooled copper mold (primary cooling zone) extracts the heat of the metal causing its solidification. The mold oscillates in order to prevent sticking with the casting.

When the casting goes out from the mold it is cooled in the secondary cooling zone by water (or water with air) sprayed on the casting surface.

Most of vertical continuous casting machines are equipped with strand guide units bending the casting and changing its configuration from vertical to horizontal.

The casting is continuously extracted from the mold by the withdrawal unit followed by a cut-off unit.

The casting process begins from inserting a dummy (primary) bar into the mold.

Then a molten metal is poured into the mold where it solidifies and grips the end of the dummy bar.

The dummy bar is disconnected from the casting after passing the withdrawal unit.

Direct Chill (DC) casting method is used for vertical semi-continuous casting of non-ferrous metals (Aluminum alloys, Copper alloys, Magnesium alloys).

to top

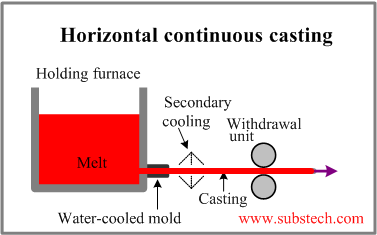

Horizontal continuous casting

Horizontal continuous casting machine is generally used for casting non-ferrous alloys. Horizontal continuous casting in stationary mold with graphite water-cooled molds, Twin-roll caster and Twin-belt caster are most popular methods of this type.

Horizontal continuous casting machine is generally used for casting non-ferrous alloys. Horizontal continuous casting in stationary mold with graphite water-cooled molds, Twin-roll caster and Twin-belt caster are most popular methods of this type.

Due to the water cooling (primary and secondary) solidification rate provided by continuous casting is higher than in other casting methods therefore continuous castings have more uniform and finer grain structure and enhanced mechanical properties.

to top

Related internal links

to Metals

to Foundry technologies