Main page

About us

Sliding Bearings Consulting

Advertising Opportunities

SubsTech’s sister website Smooth Sliding provides independent engineering consulting services that help you to solve engine bearing related issues: failures, material selection, geometry design and optimization of hydrodynamic conditions.

Smooth Sliding is an engineering consulting company run by Dr. Dmitri Kopeliovich:

- VP R&D of King Engine Bearings.

- World leading expert (32 years of experience) in design, technology and materials for Engine bearings in applications such as automotive, renewable energy, aviation, racing and others.

- Founder and owner of SubsTech (Substances & Technologies) – a leading professional website on Materials Science and Engineering.

- Author of numerous scientific and engineering publications and patents.

- Founder and owner of Smooth Sliding.

For further information and for requesting consulting services please visit our sister website Smooth Sliding.

to Metals

to Engine bearings

Heavy Duty Engine Bearings - Materials, Geometry, Failures

Bearings in Heavy Duty Engines

Heavy Duty Engines are commonly attributed to the diesel engines used for freight movement vehicles. However this category includes not only diesel engines and not only freight movement vehicles. Heavy duty engines fueled with Liquefied Petroleum Gas (LPG) become popular due to their lower emission of the nitrogen oxide and greenhouse gases. Biodiesel - renewable fuel derived from plants or animals is also an alternative to the common diesel fuel. Another type of renewable energy source used in the heavy duty engines is landfill gas (LFG) or biogas produced from organic waste materials and composed mostly of methane. Besides freight movement vehicles, heavy duty engines are used in construction equipment (bulldozers, excavators), dump trucks, agriculture equipment, emergency vehicles, ships, locomotives and various industrial applications. Biogas heavy duty engines coupled with electricity generators work in the landfill power generation plants.

The types of sliding engine bearings facilitating rotation movement of various engine parts:

- Main bearings

- Connecting rod big end bearings

- Connecting rod small end bushings

- Camshaft bearings/bushings

- Thrust washers

- Balancer shaft bearings/bushings

- Rocker arm bushings

- Valve lifter rollers

- Fuel pump adapter bushings

- Transmission bushings (counter shaft gear, PTO, gear pump, etc.)

The operation conditions of the bearings (load, lubrication, speed) as well as materials they are made are different. The failure modes are also different.

The article is a review of the extensive work and many years of experience of Smooth Sliding in various aspects of Heavy Duty Engine Bearings:

- Failure analysis of Heavy Duty Engine Bearings

- Development of Heavy Duty Engine Bearings for OEM and aftermarket applications

- Investigation of materials and structure of Heavy Duty Engine Bearings

- Development of new engine bearing materials

- Theoretical simulations of bearing operation

- Optimization of hydrodynamic lubrication

- Design of bearing geometry

- Functional and mechanical testing engine bearings

- Verification and validation (V&V) of Heavy Duty Engine Bearings

- Development and optimization of technological processes for engine bearing manufacturing

Materials of Heavy Duty Engine Bearings

Reliable and durable performance of engine bearings is determined by two general factors: properties of the bearing material and hydrodynamic conditions of lubrication.

Engine bearings work under conditions of alternating loads transmitted to the bearing surface either through the oil film or directly when the shaft contacts and rubs the bearing surface. The conditions (load, metal-to-metal contact, properties of oil, imperfectness of geometry) determine specific requirements to the engine bearing materials:

- Fatigue strength (load capacity) is the maximum value of cycling stress that the bearing can withstand after an infinite number of cycles. Cycling stresses applied to the bearings are the result of combustion and inertia forces developed in the internal combustion engines. If the bearing loading exceeds its fatigue strength fatigue cracks form in bearing material, spread to the back bearing layer and may result in flaking out of the material.

- Compatibility (seizure resistance) is the ability of the bearing material to resist physical joining with the journal material when the direct metal-to-metal contact between the bearing and journal surfaces occurs. High seizure resistance is important when the bearing works in the mixed regime of lubrication.

- Wear resistance is the ability of the bearing material to maintain its dimensional stability (oil clearance) despite the presence of abrasive foreign particles in the oil and under the conditions of intermittent direct contact between the bearing and journal materials.

- Conformability is the ability of the bearing material to accommodate geometry misalignments of the bearing, its housing or journal. Shape irregularities of a bearing with poor conformability may cause localized decrease of the oil film thickness to zero where the bearing material experiences excessive wear and high specific loading.

- Embeddability is the ability of the bearing material to entrap and sink beneath the surface small foreign particles (dirt, debris, dust, abrasive residuals) circulating in the lubricating oil. Poor embeddability of a bearing material causes accelerated wear and produces scratches on the journal and bearing surfaces, which may lead to seizure.

- Corrosion resistance is the ability of the bearing materials to resist chemical attack of oxidized and impure lubricants.

- Cavitation resistance is the ability of the bearing material to withstand impact stresses caused by collapsing cavitation bubbles, which form as a result of sharp and localized drops of pressure in the flowing lubricant.

The properties are contradictory. Fatigue strength, wear resistance and cavitation resistance are attributed to the material strength, whereas seizure resistance, conformability and embeddability relate to the material softness. In order to achieve required compromise between the properties the engine bearing materials are designed to have a composite structure.

The simplest material used for the Heavy Duty Engine Bearings has a bi-metallic structure: steel back and bearing lining made of an aluminum or copper alloy.

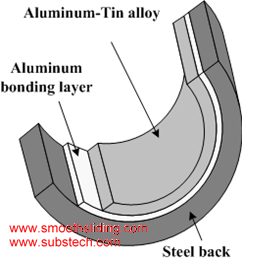

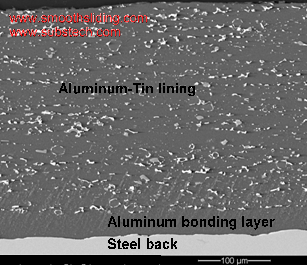

Fig.1 depicts the structure of a Heavy Duty Engine Bearing having bimetallic structure with aluminum-tin lining. Bimetallic aluminum bearings always contain dispersed tin serving as a solid lubricant. In some Heavy Duty Engines main bearings and camshaft bearings have bimetallic structure.

Fig.1 Structure of Bimetallic Heavy Duty Engine Bearing with Aluminum Lining

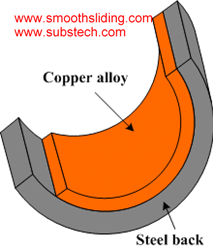

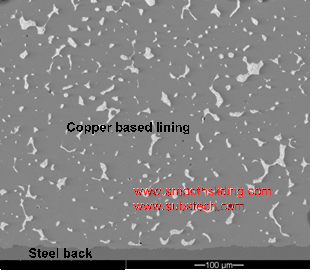

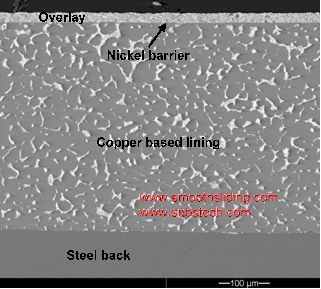

Bimetallic bearings with copper based (bronze) lining (Fig.2) are used in all Heavy Duty Engines as bushings mounted in the small end of the connecting rod. Bimetallic steel-bronze material is also used in the rocker arm bushings. The copper alloy contains tin and may also contain lead as a solid lubricant.

Fig.2 Structure of Bimetallic Heavy Duty Engine Bearing with Bronze Lining

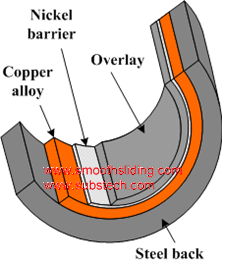

The high loads developed in the Heavy Duty Engines require bearings with greater load capacity. Trimetallic bearings with strong bronze lining have higher (as compared to the bimetallic aluminum materials) fatigue strength. The surface properties (conformability, seizure resistance, embeddability) are provided by a thin relatively soft coating. Typical structure of a trimetallic bearing with bronze lining is depicted in Fig.3. Commonly the overlays are made of an electrolytically deposited leaded alloy. A thin nickel diffusion barrier is applied between the lining and the overlay. In some modern Heavy Duty Engines the overlay is made of a polymer based coating containing dispersed particles of a solid lubricant (molybdenum disulfide, hexagonal boron nitride, graphite or PTFE). In some Heavy Duty applications with particularly high loads applied to the upper rod and lower main bearings a strong sputter coating is used as the overlay. Sputter coatings are composed of aluminum-tin alloys deposited by Magnetron Sputtering Physical Vapor Deposition. Bronze trimetallic connecting rod bearings, main bearings and camshaft bearings are used in most Heavy Duty Engines.

Fig.3 Structure of Trimetallic Heavy Duty Engine Bearing with Bronze Lining

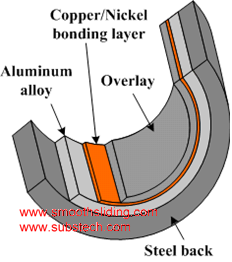

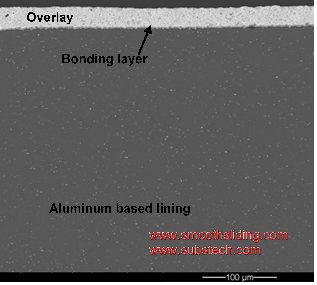

In some Heavy Duty Engine Bearings (main bearings, connecting rod bearings) aluminum linings are used in the trimetallic material structure (Fig.4). The aluminum alloys used in the trimetallic aluminum bearings are harder and stronger than aluminum-tin alloys of the bimetallic bearings. The overlays of the trimetallic Heavy Duty Engine Bearings are made of soft lead-tin alloys deposited by electrolytic process. Nickel or copper are used as the thin bonding layer applied between the aluminum lining and coating.

Fig.4 Structure of Trimetallic Heavy Duty Engine Bearing with Aluminum Lining

Monometallic (solid) materials are rarely used in engine bearing applications. Nevertheless, the valve roller lifters of some Heavy Duty Engines are equipped with solid bronze bearings (Fig.5).

Fig.5 Valve Roller Lifter with Solid Bronze Pin

to top

Geometry and Hydrodynamic Lubrication of Heavy Duty Engine Bearings

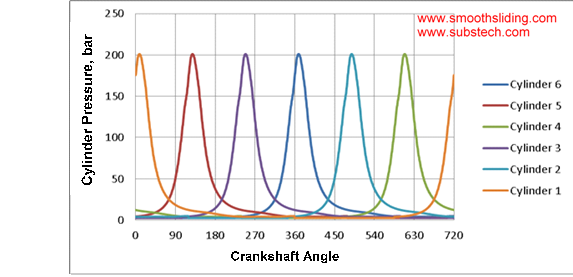

Theoretical simulations of engine bearing performance under various conditions are capable of calculating the thermodynamic, dynamic, hydrodynamic and mechanical parameters of bearing operation. The simulations start from calculating the combustion process in the cylinders (Fig.6).

Fig.6 Pressure Diagram in Cylinders of L-6 Heavy Duty Engine Bearings

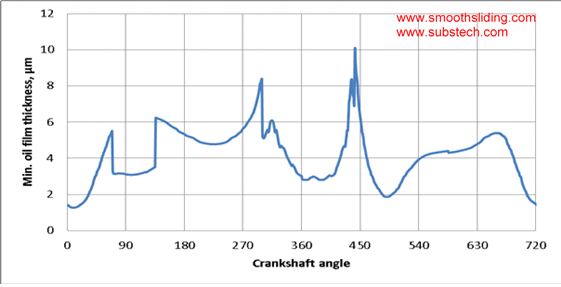

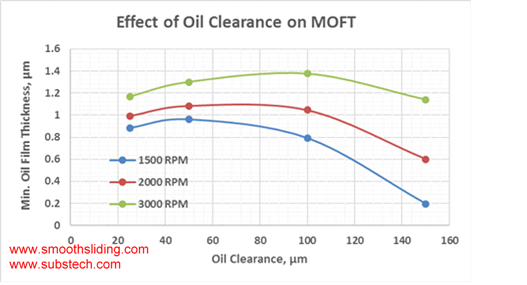

Engine bearings function as hydrodynamic bearings, in which a rotating journal produces a hydrodynamic force pressurizing the lubricant flowing between the journal and the bearing surfaces. The pressure does not allow the journal to contact the bearing surface since it acts in the direction opposite to the direction of the external load. The surfaces are separated by a film of oil that is being continuously squeezed through the gap between the journal and the bearing. The main objective of the hydrodynamic calculations is to determine the optimal values of clearance for various operational conditions. The most important hydrodynamic parameter affected by oil clearance is the value of minimum oil film thickness. Fig.7, 8 depict examples of calculations of the minimum oil film thickness in Heavy Duty Engine Bearings.

Fig.7 Minimum Oil Film Thickness in Main Bearing of L-6 Heavy Duty Engine

Fig.8 Minimum Oil Film Thickness in Rod Bearing of Four Cylinder Heavy Duty Engine

to top

Press Fit of Heavy Duty Engine Bearings

A firmly tightened bearing has uniform contact with the housing surface, which fulfills the following functions:

- Prevents bearing fretting and spinning in the housing during operation

- Provides maximum heat transfer through the contacting surfaces

- Increases the rigidity of the housing

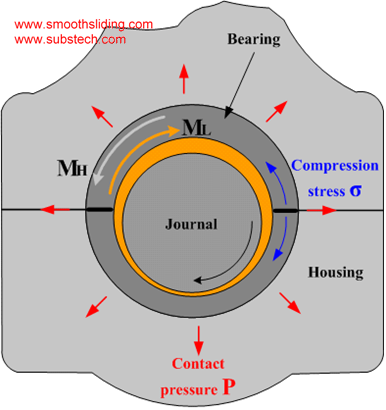

Fig.9 depicts a bearing installed in the housing. When the bearing is assembled and the two parts of the housing are tightened, a compression stress σ in the circumference direction of the bearing back is formed. The stress causes the bearing to press to the housing surface at a contact pressure P. The value of the radial contact pressure P determines the ability of the bearing to transfer the heat produced by friction. The contact pressure also produces a friction between the bearing back and the housing surface which contradicts the friction generated by the journal rotating in the bearing (ML). The torque of the friction force formed between the bearing back and the housing MH prevents the bearing from shifting in the housing.

Fig.9 Bearing Assembly

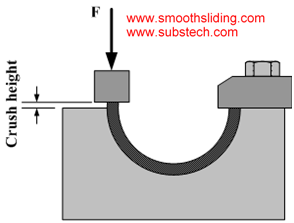

In order to achieve a required contact pressure, the outside diameter of an engine bearing is produced greater than the diameter of its housing. Since direct measurement of the bearing circumference is a difficult task, another parameter characterizing the bearing press fit is commonly measured - crush height. Crush height is the difference between the outside circumferential length of a half bearing and half of the housing circumference measured at a certain press load (Fig.10).

Fig.10 Device for Measuring Crush Height

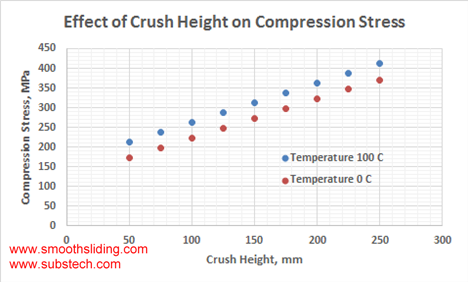

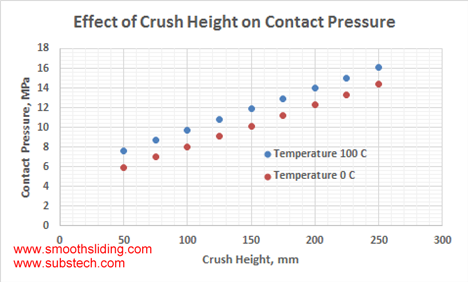

Examples of calculations of an effect of crush height on the compression stress and contact pressure are depicted in Fig.11, 12.

Fig.11 Effect of Crush Height on Compression Stress in Heavy Duty Main Bearing in Cast Iron Housing (example)

Fig.12 Effect of Crush Height on Contact Pressure in Heavy Duty Main Bearing in Cast Iron Housing (example)

to top

Failures of Heavy Duty Engine Bearings

Fatigue

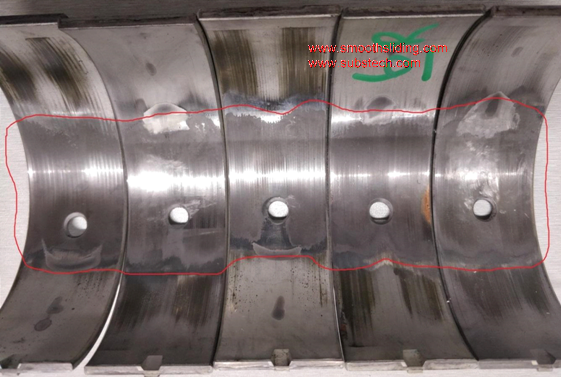

The major type of engine bearing failure is material fatigue. It is caused by running the bearing at load above the fatigue limit. If load acting to the bearing is higher than the fatigue strength of the material, fatigue cracks form on the bearing surface, spread towards the back layer and may result in peeling off the bearing material. An example of a Heavy Duty Engine Bearing affected with fatigue of the bronze lining is depicted in Fig.13.

Fig.13 Fatigue of Bronze Lining of Heavy Duty Rod Bearing

Wear

Excessive wear of the bearing overlay or lining caused by an abrasive action of the shaft reduces the bearing service life and may cause its catastrophic failure. Heavy Duty Engine Bearings having substantial zones of excessive wear are depicted in Fig.14.

Fig.14 Wear of Overlay of Heavy Duty Rod Bearings

Seizure

Under certain conditions the bearing material may form a strong metallurgical bonding with the shaft material, which results in the bearing seizure. An image of a seized Heavy Duty Engine Bearing is presented in Fig.15.

Fig.15 Seizure of Heavy Duty Main Bearing

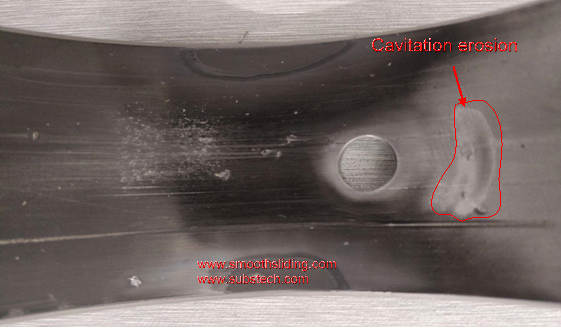

Cavitation Erosion

Cavitation erosion of bearing material is formed under the conditions of fast changes of the oil pressure. The oil pressure can instantly fall, causing formation of oil vapor cavities (bubbles). When the pressure rises, cavitation bubbles contract at high velocity. Such collapse results in impact pressure that can erode the bearing material. An example of cavitation erosion of the soft overlay of a Heavy Engine Bearing is depicted in Fig.16.

Fig.16 Cavitation Erosion of Heavy Duty Rod Bearing

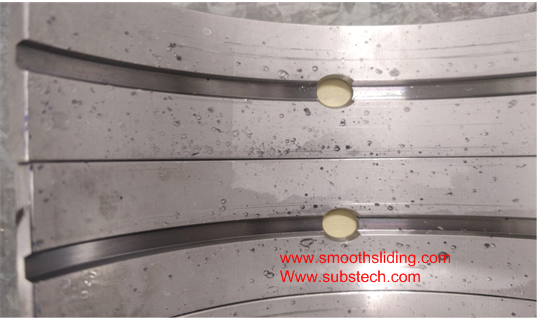

Contaminated Oil

Foreign particles circulating in oil may enter the gap between the bearing and journal and produce abrasive wear in the form of circumferential scores or scratches on the bearing surface. Some of the contaminating particles may embed into the bearing surface (Fig.17).

Fig.17 Contaminating Debris Embedded into Lining of Heavy Duty Main Bearings

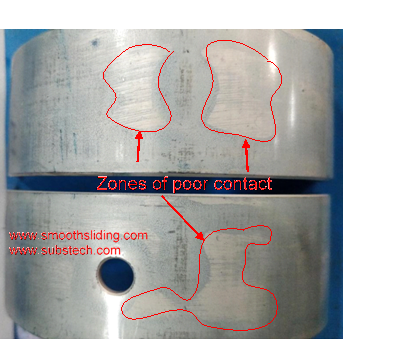

Poor Fitting

Even bearings having optimal value of crush height may not provide proper contact between the bearing back and the housing surface. This occurs when the bearing was fabricated with an imperfect back profile. The quality of the bearing back fitting contact is checked in the device of crush height measurement (Fig.10) by means of Prussian Blue compound spread over the housing tool. Fig.18 depicts an example of poor back fitting of Heavy Duty Engine Bearings.

Fig.18 Poor Back Fitting of Heavy Duty Rod Bearings

Corrosion

In presence of water and oxygen the lubricating oil oxidizes and degrades. Its acidity rises, additives depletes and the viscosity increases. Acidic (oxidized) oil attacks the metallic parts of the engine and causes their corrosion. Leaded alloys are prone to corrosion in oxidized lubricants. Corrosion of the lead based overlay and leaded bronze of a Heavy Duty Engine Bearing is presented in Fig.19.

Fig.19 Corrosion of Lead in Heavy Duty Engine Bearing

to top

Summary

The article reviews various aspects of Heavy Duty Engine Bearings on the base of the experience and knowledge accumulated by Smooth Sliding in design, development, material investigations and failure analysis of bearings for heavy duty applications.

The following subjects are considered:

- Requirements to the bearing materials

- Structure and composition of different materials for Heavy Duty Engine Bearing

- Bearing design and its effect on the hydrodynamic parameters of lubrication

- Typical failure modes of Heavy Duty Engine Bearings

Related internal links

to Metals

to Engine bearings