Main page

About us

Sliding Bearings Consulting

Advertising Opportunities

SubsTech’s sister website Smooth Sliding provides independent engineering consulting services that help you to solve engine bearing related issues: failures, material selection, geometry design and optimization of hydrodynamic conditions.

Smooth Sliding is an engineering consulting company run by Dr. Dmitri Kopeliovich:

- VP R&D of King Engine Bearings.

- World leading expert (32 years of experience) in design, technology and materials for Engine bearings in applications such as automotive, renewable energy, aviation, racing and others.

- Founder and owner of SubsTech (Substances & Technologies) – a leading professional website on Materials Science and Engineering.

- Author of numerous scientific and engineering publications and patents.

- Founder and owner of Smooth Sliding.

For further information and for requesting consulting services please visit our sister website Smooth Sliding.

to Metals

to Engine bearings

Materials for Engine Bearings

Engines and engine bearings

The first usable internal combustion engine was patented in 1860 by the Belgian engineer Jean Joseph Etienne Lenoir.

Its thermodynamic cycle was less effective than the later engines invented by Otto and Diesel. However the principal mechanical parts of all earliest engines were the same: a combustion cylinder, a piston, a connecting rod, a crankshaft, a flywheel and bearings (a couple of main bearings and a rod bearing).

Mechanical energy of a rotating crankshaft was generated in the process of combustion of fuel-air mixture taking place inside of a cylinder. Gases formed as a result of combustion increased pressure in the cylinder. Pressure pushed the piston, performing linear reciprocating motion along the cylinder. The piston and the eccentric crankpin journal of the crankshaft were tied by a connecting rod. By means of the connecting rod reciprocating motion of the piston was converted into rotating motion of the crankshaft.

A connecting rod bearing provided rotating motion of the crankpin within the connecting rod.

Two main crankshaft bearings supported the rotating crankshaft. The main bearings were mounted in the crankcase.

It is amazing that despite of a huge progress in engine design that has been made for the last 150 years, the basic principles of thermodynamic and of the mechanical structure of the internal combustion engines has not been changed. The engine bearings have not been principally changed as well. As a matter of fact engine bearings had been invented and used even before the internal combustion engine was invented. Engine bearings had been used in steam engines having the same principle of transformation of reciprocating energy into rotation.

From the beginning engine bearings have been lubricated sliding bearings. In very early steam engines they were lubricated with tallow and later with oil.

The automotive engines have been lubricated with motor oils. And the engine bearings are principally may be referred as hydrodynamic journal bearing - bearings operating with hydrodynamic lubrication, in which the bearing surface is separated from the journal surface by the lubricant film generated by the journal rotation.

Unfortunately pure hydrodynamic lubrication is an ideal condition which is not achievable in the real engines. Direct contact between a bearing and the journal surfaces occurs intermittently.

However metal-to-metal contact is not the only challenge faced by the bearings. Engine bearings experience load generated in the cylinder and transmitted with the connecting rod. Since the combustion process is cycling, the load is also cycling. The bearing operates under alternating mechanical stress which may cause the material Fatigue.

to top

Requirements for Materials for Engine Bearings

The conditions (alternating load, metal-to-metal contact, properties of oil, imperfectness of bearing geometry) determine specific requirements to the engine bearing materials:

- Fatigue strength (load capacity) is the maximum value of cycling stress that the bearing can withstand after an infinite number of cycles. Cycling stresses applied to the bearings are the result of combustion and inertia forces developed in internal combustion engines. If the bearing loading exceeds its fatigue strength fatigue cracks form in the bearing material, spread to the back bearing layer, and may result in flaking out of the material.

- Compatibility (seizure resistance) is the ability of the bearing material to resist physical joining with the journal material when direct metal-to-metal contact between the bearing and journal surfaces occurs. High seizure resistance is important when the bearing works in the mixed regime of lubrication.

- Wear resistance is the ability of the bearing material to maintain its dimensional stability (oil clearance) despite the presence of abrasive foreign particles in the oil and under the conditions of intermittent direct contact between the bearing and journal materials.

- Conformability is the ability of the bearing material to accommodate geometry misalignments of the bearing, its housing, or journal. Shape irregularities of a bearing with poor conformability may cause a localized decrease of the oil film thickness to zero where the bearing material experiences excessive wear and high specific loading.

- Embeddability is the ability of the bearing material to entrap and sink beneath the surface small foreign particles (dirt, debris, dust, abrasive residuals) circulating in the lubricating oil. Poor embeddability of a bearing material causes accelerated wear and produces scratches on the journal and bearing surfaces, which may lead to a seizure.

- Corrosion resistance is the ability of the bearing materials to resist chemical attack of oxidized and impure lubricants.

- Cavitation resistance is the ability of the bearing material to withstand impact stresses caused by collapsing cavitation bubbles, which form as a result of sharp and localized drops of pressure in the flowing lubricant.

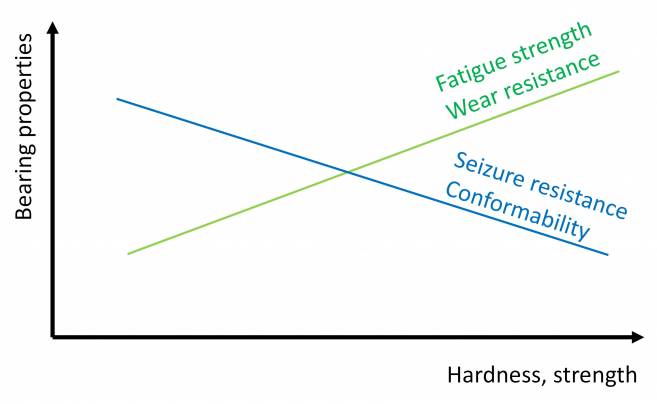

The properties are contradictory. Fatigue strength, wear resistance, and cavitation resistance are attributed to the material’s strength, whereas seizure resistance, conformability, and embeddability relate to the material softness (Fig.1).

Fig.1 Contradiction of Requirements to Materials for Engine Bearings

To achieve required compromise between the properties the engine bearing materials are designed to have a composite structure.

The structure may be either layered with a soft overlay applied over a strong lining or particulate, in which small particles of soft material are distributed in a relatively strong matrix.

Some bearings combine layered and particulate composite structures.

to top

Bimetallic Steel-Aluminum Bearings

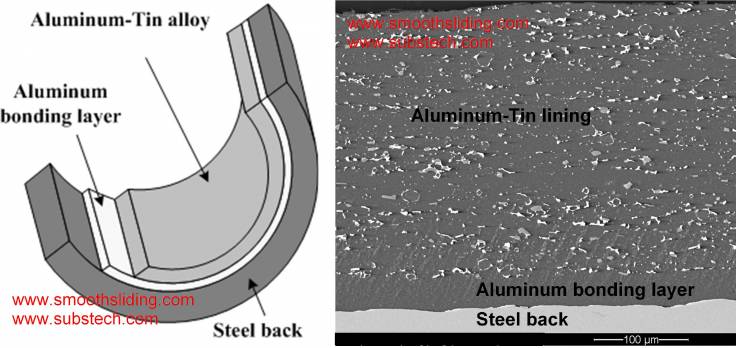

Fig.2 depicts the structure of a bearing having a bimetallic structure with aluminum-tin lining.

Fig.2 Bimetallic Structure of Engine Bearings with Aluminum Lining

Bimetallic aluminum bearings always contain dispersed tin serving as a solid lubricant.

A typical bi-metal bearing (Fig.3) consists of a steel back and a lining of about 0.01-0.015” (0.25-0.4 mm) thick made of an antifriction aluminum alloy.

Fig.3 Bimetallic Engine Bearings with Aluminum Lining

Aluminum bearing alloys commonly contain tin (6-40%) as a soft component distributed in the aluminum matrix in the form of a separate phase. Tin particles provide the anti-friction properties (compatibility, conformability, embedability).

Some aluminum bearing alloys contain silicon (2-4%). Silicon has very high hardness and its inclusions distributed throughout the aluminum matrix strengthen the alloy and also serve as an abrasive polishing the mating journal surface.

The aluminum matrix of engine bearing alloys may be strengthened by the addition of copper, nickel, chromium, manganese, magnesium, zinc, and vanadium.

The typical load capacity of the bimetallic bearings with aluminum-tin lining is 40-60 MPa (5,800-8,700 psi).

to top

Trimetallic Steel-Bronze-Babbitt Bearings

High loads developed require bearings with greater load capacity. Trimetallic bearings with strong bronze lining have higher (as compared to the bimetallic aluminum materials) fatigue strength. The surface properties (conformability, seizure resistance, embeddability) are provided by a thin soft coating.

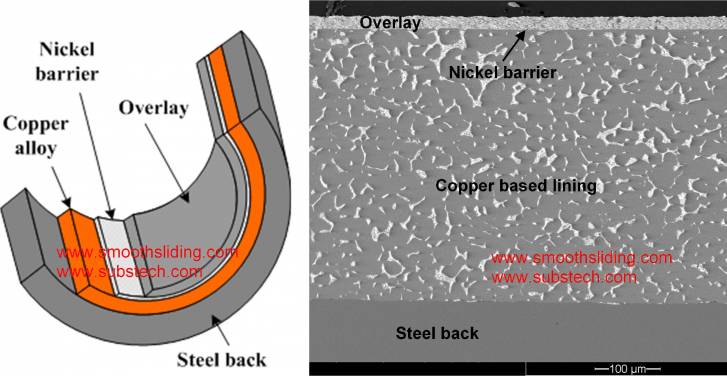

The typical structure of a trimetallic bearing with bronze lining is depicted in Fig.4.

Fig.4 Trimetallic Structure of Engine Bearings with Bronze Lining

Conventional trimetallic bearings (Fig.5) are composed of leaded materials: leaded bronze and lead-based overlays. Lead is an excellent solid lubricant having been used in antifriction applications since 1839 when lead-based and tin-based alloys (babbitts) were invented by the American engineer Isaac Babbitt.

Fig.5 Trimetallic Engine Bearings with Bronze Lining and Leaded Overlay

Because of environmental restrictions implemented in many countries leaded materials are being displaced by lead-free bearings. However, leaded bearings are still popular in many applications such as racing cars, industrial and aviation engines.

A tri-metal bearing consists of a steel back, an intermediate bearing layer, and an overlay.

The lining of about 0.01-0.015” (0.25-0.4 mm) thick is made of a copper bearing alloy with moderate or low anti-friction properties (conformability, compatibility, embedability) but high fatigue strength. The intermediate layer has a certain level of surface (antifriction) properties which are necessary for preventing catastrophic failure of the bearing in emergency conditions of metal-to-metal contact (boundary or mixed lubrication), oil starvation, significant misalignments or journal deflections.

Copper alloys such as CuPbSn (leaded bronzes), CuBiSn, CuSnNi are used as linings. Copper-based materials are applied onto the steel back surface by either casting or sintering process. The leaded bronzes used in tri-metal bearings contain 20-25% of lead and 1-5% of tin.

A typical engine bearing overlay is a thin (0.0005-0.0008”/13-20 µm) surface layer made of a soft material (e.g. Pb10Sn3Cu) and having very good ant-friction properties (compatibility, conformability, embedability). The overlay is applied by electroplating onto the surface of the bearing lining after the final machining operation (boring or broaching).

A nickel diffusion barrier (nickel dam) is deposited between the intermediate layer and the overlay in order to prevent migration of tin from the overlay into the bronze lining. The decrease of the tin content in the overlay due to its migration into the lining deteriorates the corrosion resistance of the lead-based overlay alloys. The thickness of the nickel diffusion barrier is about 0.00004”-0.00008” (1-2 µm).

The typical load capacity of the trimetallic bearings with a babbitt overlay is 60 MPa (8,700 psi).

to top

Bimetallic Steel-Bronze Bushings

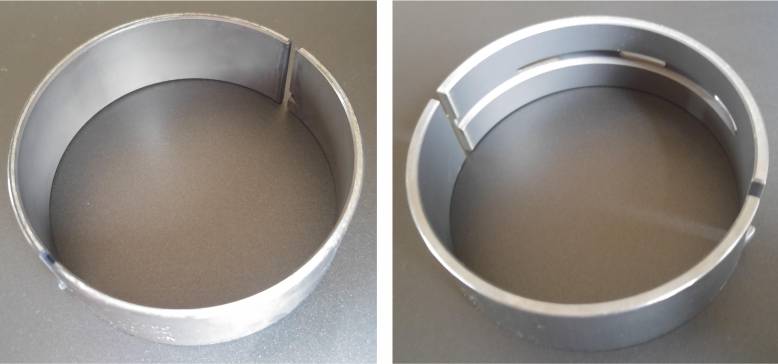

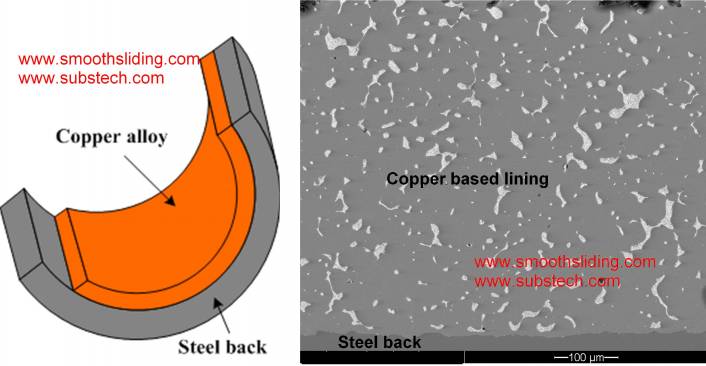

Bimetallic bearings with copper-based (bronze) lining (Fig.6, 7) are used as bushings mounted in the small end of the connecting rod. Bimetallic steel-bronze material is also used in the rocker arm bushings in valvetrain mechanisms.

Fig.6 Bimetallic Structure of Bushing with Bronze Lining

The copper alloy contains tin and may also contain lead as a solid lubricant.

Fig.7 Bimetallic Bushings with Bronze Lining

to top

Trimetallic Steel-Aluminum-Babbitt Bearings

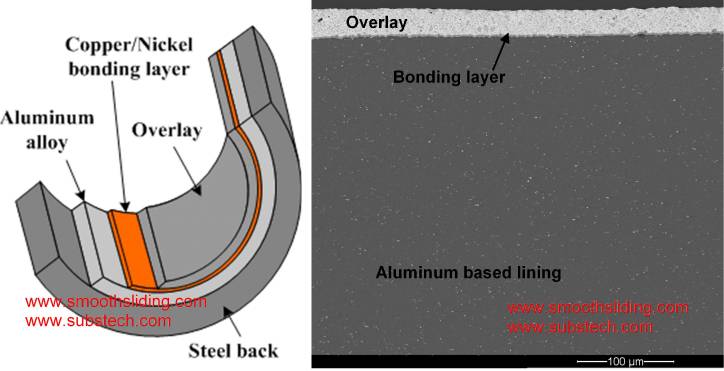

In some heavy duty engine bearings, aluminum linings are used in the trimetallic material structure (Fig.8, 9).

Fig.8 Trimetallic Structure of Engine Bearings with Aluminum Lining

Fig.9 Trimetallic Heavy Duty Engine Bearings with Aluminum Lining

The aluminum alloys used in the trimetallic aluminum bearings contain silicon, zinc, copper, and magnesium but no tin. They are harder and stronger than aluminum-tin alloys of the bimetallic bearings. The overlays are made of soft lead-tin alloys deposited by an electrolytic process.

Nickel or copper is used as a thin bonding layer applied between the aluminum lining and coating.

The typical load capacity of the trimetallic bearings with aluminum lining is 60 MPa (8,700 psi).

to top

Sputter Bearings

In most artificially aspirated diesel engines the load applied to the bearings (particularly to the upper parts of the rod bearings) exceeds the fatigue strength of conventional bimetallic and trimetallic materials.

Diesel engines are characterized by a high compression ratio (17-22). Therefore they have an advantage in thermal efficiency as compared to spark ignition engines (e.g. gasoline).

Forced induction (turbocharging or supercharging) is the most effective method to increase the power and torque of engines. Boost pressure increases the actual amount of air entering the cylinders. Correspondingly the amount of fuel intaken and combusted in every cycle is also increased. Thus the output horsepower and torque are considerably greater than in naturally aspirated engines.

Due to the high compression ratio and forced aspiration the combustion pressure in the cylinders of a diesel engine is very high and may reach 200-230 bar.

Such a high cylinder pressure being transmitted by the connecting rod exerts a large alternating load acting on the upper rod bearing half. The specific load may reach 100-120 MPa (14,500-17,400 psi).

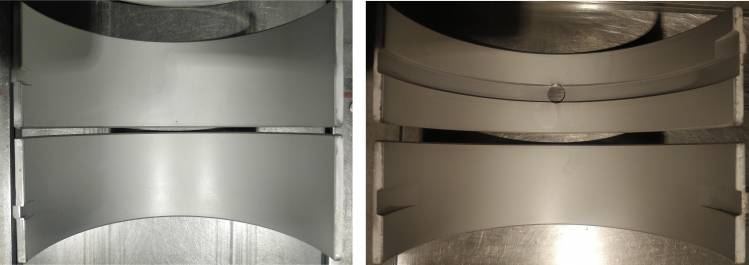

Very few materials are capable to withstand such loads. One of them is sputter material used for the fabrication of highly loaded engine bearings (Fig.10).

Fig.10 Sputter Bearing

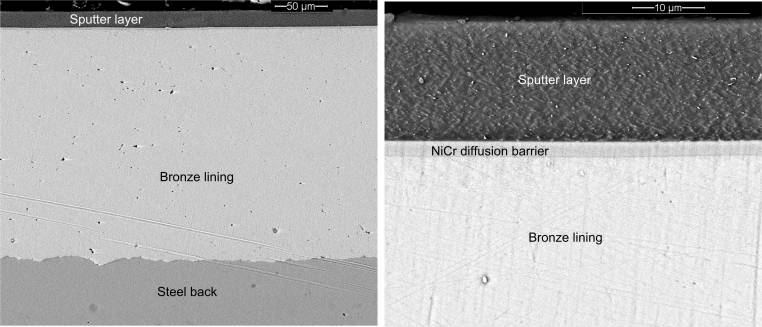

Sputter bearings have a trimetallic structure (Fig.11).

Fig.11 Microstructure of Sputter Bearing

A sputter bearing is composed of a steel back, lead-free high strength bronze lining, and AlSn sputter overlay having a thickness ~ 16 µm (0.00064”).

The nickel-chromium diffusion barrier is deposited between the intermediate layer and the sputter overlay to prevent the migration of tin from the overlay into the bronze lining. The thickness of the diffusion barrier is about 0.00004”-0.00008” (1-2 µm).

Sputter overlays are deposited by the Sputtering method (Physical Vapor Deposition (PVD)). Sputtering utilizes argon ions for bombarding a catholically connected target, made of the coating material (normally Al20Sn or Al40Sn). The resulting material has an extremely uniform aluminum-tin microstructure. Due to the deposition of the alloy by the PVD technique hardness of the AlSn alloy reaches 100 HV (Vickers).

The load capacity of sputter bearings is 120 MPa (17,400 psi).

to top

High Strength Silver Coated Bearings

King Engine Bearings has developed silver coated bearings (Fig.12) having load capacity as high as the sputter material.

Fig.12 High Strength Silver Coated Bearing

A silver bearing is composed of steel back, high strength lead-free bronze lining, silver-based coating having thickness ~ 12 µm (0.0005”), and a relatively soft top layer made of either lead-based alloy or lead-free antifriction polymer coating.

The top layer imparts the bearings excellent antifriction properties (conformability, seizure resistance, and embedability).

The load capacity of silver bearings is 120 MPa (17,400 psi).

to top

Antifriction Polymer Coatings

Initially, polymer coatings containing particles of Solid lubricants were developed for start-stop engines in which frequent events of direct non-hydrodynamic friction during accelerating-decelerating start-stop cycles are unavoidable. However, polymer-based anti-friction coatings have proved their effectiveness also in other applications.

Any anti-friction polymer-based coating is composed of a polymer matrix containing dispersed particles of a solid lubricant (molybdenum disulfide, hexagonal boron nitride, graphite, PTFE). Coatings may also contain other dispersed substances enhancing mechanical properties and wear resistance.

Generally, polymer coatings developed by King Engine Bearings are composed of the following constituent:

- A polymer matrix.

- Nano-size particles of the solid lubricant.

- Hard nano-size particles. Those particles provide wear resistance. They also improve the crankshaft surface quality due to the effect of polishing micro-scores on its surface.

- An additive in the form of nano-size particles enhancing the coating toughness and fatigue strength.

Coating promotes the conforming of the bearing surface resulting in lower wear of the bearing material.

Components of the coating have excellent anti-friction properties (very high seizure resistance, low coefficient of friction, embedability, conformability).

Polymer coatings may be deposited as a top layer onto any bearing material - bimetallic bearings with aluminum lining, trimetallic bearings with leaded overlay, sputter, and silver bearings (Fig.13).

Fig.13 Polymer Coated Bearing

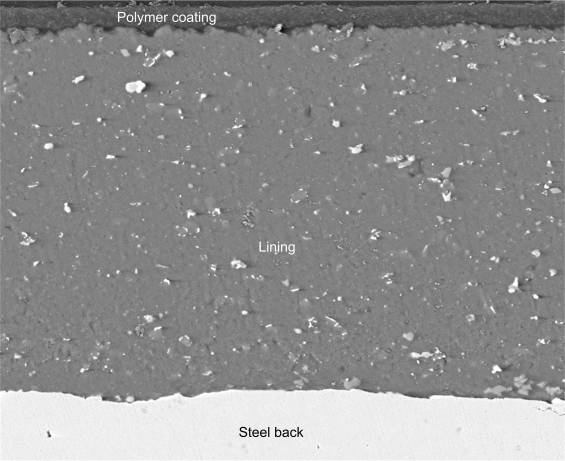

Fig.14 depicts a microstructure of a polymer coated bearing.

Fig.14 Microstructure of Polymer Coated Bearing

to top

Materials for High Performance Bearings

The classic traditional bearing materials are not capable of withstand the severe conditions of modern racing engines.

Since engine efficiency and output have increased considerably over the last years, specific loads applied to the bearings have also increased. In addition to greater loading, there is also a trend to use reduced viscosity motor oils which lower the power losses caused by friction. As a result, bearings in modern race engines work at higher loads and with lower minimum oil film thicknesses. The load capacity and wear resistance of traditional tri-metal materials may be inadequate for some high performance applications.

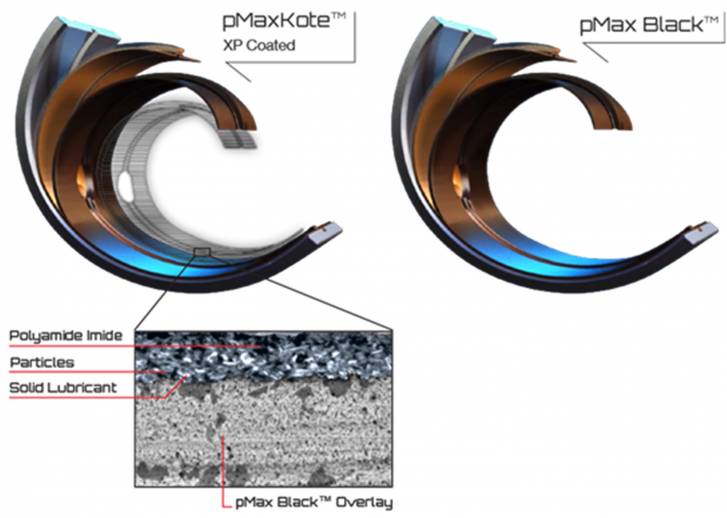

King Engine Bearings has solved this problem with its strengthened tri-metal material, pMax Black™ (XP), specifically developed for highly loaded race engines. This development comprises an innovative technique that enables the formation of an ultra-thin hardened shield on the overlay surface. This shield, of nano-scale thickness, considerably reduces overlay wear. It also effectively suppresses the formation of fatigue cracks on the overlay surface. XP bearings (Fig.15) withstand greater loads without the formation of fatigue cracks and distress. The load capacity of XP bearings is 10,200 psi (70 MPa).

At the same time, the properties of excellent seizure resistance, conformability, and embedability – which are characteristics of soft overlays – are preserved.

Fig.15 XP Bearing for Racing Applications

Further development of engine bearings is the coated version of XP bearings.

pMax Kote™ (XPC) is the King principal polymer coated race engine bearing material. Its surface is coated with the K-334 coating - wear resistant polymer developed for applying over a relatively soft substrate of the tri-metal pMax Black™ (XP) high performance bearings (Fig.16). The coating helps to improve XP bearing wear resistance under conditions of metal-to-metal contact.

Fig.16 Structure of XP and XPC High Performance Bearings

to top

Summary

- Requirements for materials for #EngineBearing were explained.

- Conventional bimetallic and trimetallic engine bearing materials were characterized (structure, composition, applications).

- High load capacity sputter and silver coated engine bearing were described.

- The purpose, general composition, and applications of polymer based antifriction coatings were explained.

- Materials for high performance engine bearings were characterized.

Related internal links

to Metals

to Engine bearings