SubsTech’s sister website Smooth Sliding provides independent engineering consulting services that help you to solve engine bearing related issues: failures, material selection, geometry design and optimization of hydrodynamic conditions.

Smooth Sliding is an engineering consulting company run by Dr. Dmitri Kopeliovich:

- VP R&D of King Engine Bearings.

- World leading expert (32 years of experience) in design, technology and materials for Engine bearings in applications such as automotive, renewable energy, aviation, racing and others.

- Founder and owner of SubsTech (Substances & Technologies) – a leading professional website on Materials Science and Engineering.

- Author of numerous scientific and engineering publications and patents.

- Founder and owner of Smooth Sliding.

For further information and for requesting consulting services please visit our sister website Smooth Sliding.

to Metals

to Engine bearings

Bearings in internal combustion engines

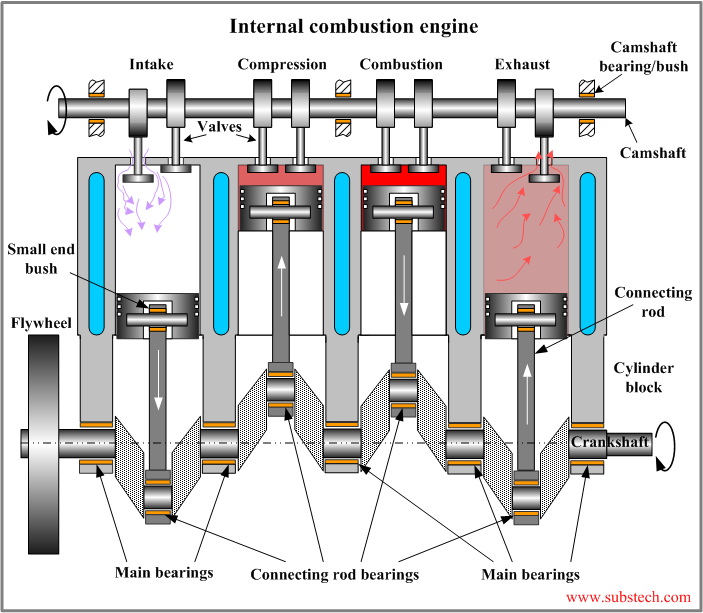

Internal combustion engine

Internal combustion engine is a device converting the energy of a fuel-air mixture burning within a combustion chamber into mechanical energy.

Reciprocating internal combustion engine is an engine, in which burning process occurs within a cylinder equipped with a piston driven by the pressure of the combustion gases. The gas pressure force is transmitted to the crankshaft linked to the piston by means of a connecting rod. Such mechanical device called crank mechanism transforms the alternating linear motion of the piston into the rotation of the shaft.

Reciprocating engines are the most common type of internal combustion engines.

The figure below presents a scheme of a typical four-stroke reciprocating combustion engine.

The engine consists of four cylinders in different phases of the engine cycle (intake, compression, expansion and exhaust). Each cylinder has an inlet and exhaust valves, opening and closing of which is controlled by the cam mechanism.

Each piston is joined to the crank pin of the crankshaft though the connecting rod.

The four-stroke cycle:

- Intake: The intake valve is open. The piston moves downwards from the Top Dead Center (TDC) to the Bottom Dead Center (BDC) sucking the fuel-air mixture into the cylinder.

- Compression: Both valves are closed. The piston moves from BDC towards TDC compressing the gaseous fuel-air mixture. The compression causes pressure and temperature increase of the gas in the cylinder. When the crankshaft reaches some angle before TDC the fuel-air mixture is ignited and fuel combustion starts. Combustion further increases the gas pressure and temperature. In the gasoline (petrol) engines ignition is as a result of a spark produced by the spark plug. The engines of such type are called Spark Ignition (SI) engines. In the diesel engines the fuel-air mixture is ignited by the heat of the compressed gages. The engines of such type are called Compression Ignition (CI) engines.

- Power (expansion): Both valves are closed. The piston travels from TDC to BDC under the high pressure of hot burning gases. The power of the the gases is transmitted to the crankshaft through the connecting rod. Just before the piston reaches the Bottom Dead Center the exhaust valve opens.

- Exhaust: The exhaust valve is open. The piston moves towards TDC forcing the combustion gases out of the cylinder. When it reaches TDC the exhaust valve closes and the intake valve opens - the cycle returns to the initial state.

Functions of bearings in internal combustion engines

Bearing is a device supporting a mechanical element and providing its movement relatively to another element with minimum power loss.

Bearing is a device supporting a mechanical element and providing its movement relatively to another element with minimum power loss.

The rotating components of internal combustion engines are equipped with sleeve type sliding bearings.

The reciprocating engines are characterized by cycling loading of their parts including bearings. Such character of the loads is a result of alternating pressure of combustion gases in the cylinders.

Rolling bearings, in which a load is transmitted by rolls (balls) to a relatively small area of the ring surface, can not withstand under the loading conditions of internal combustion engines.

Only sliding bearings providing a distribution of the applied load over a relatively wide area may work in internal combustion engines.

The sliding bearings used in internal combustion engines:

- Main crankshaft bearings support crankshaft providing its rotation under inertia forces generated by the parts of the shaft and oscillating forces transmitted by the connecting rods. Main bearings are mounted in the crankcase. A main bearing consists of two parts: upper and lower. The upper part of a main bearing commonly has an oil groove on the inner surface. A main bearing has a hole for passing oil to the feed holes in the crankshaft. Some of main bearings may have thrust bearing elements supporting axial loads and preventing movements along the crankshaft axis. Main bearings of such type are called flange main bearings.

- Connecting rod bearings provide rotating motion of the crank pin within the connecting rod, which transmits cycling loads applied to the piston. Connecting rod bearings are mounted in the Big end of the connecting rod. A bearing consists of two parts (commonly interchangeable).

- Small end bushes provide relative motion of the piston relatively to the connecting rod joined to the piston by the piston pin (gudgeon pin). End bushes are mounted in the Small end of the connecting rod. Small end bushes are cycling loaded by the piston pushed by the alternating pressure of the combustion gases.

- Camshaft Bearings support camshaft and provide its rotation.

Lubrication of the bearings in internal combustion engine

Purposes of lubrication of engine bearings are as follows:

- significant decrease of the coefficient of friction;

- extraction of the heat generated by the friction;

- removal of foreign particles from the rubbing surfaces.

Engine bearings generally work in hydrodynamic regimes of friction.

Hydrodynamic friction implies the presence of a continuous lubricant film between the bearing and journal surfaces (Hydrodynamic journal bearing).

Constant supply of a lubricant (oil) in sufficient amounts is necessary for normal work of engine bearings.

Bearings lubrication is provided by the lubrication system.

to top

Related internal links

to Metals

to Engine bearings