Main page

About us

Sliding Bearings Consulting

Advertising Opportunities

SubsTech’s sister website Smooth Sliding provides independent engineering consulting services that help you to solve engine bearing related issues: failures, material selection, geometry design and optimization of hydrodynamic conditions.

Smooth Sliding is an engineering consulting company run by Dr. Dmitri Kopeliovich:

- VP R&D of King Engine Bearings.

- World leading expert (32 years of experience) in design, technology and materials for Engine bearings in applications such as automotive, renewable energy, aviation, racing and others.

- Founder and owner of SubsTech (Substances & Technologies) – a leading professional website on Materials Science and Engineering.

- Author of numerous scientific and engineering publications and patents.

- Founder and owner of Smooth Sliding.

For further information and for requesting consulting services please visit our sister website Smooth Sliding.

to Metals

to Engine bearings

Soft Strength of Racing Bearings

Introduction

Soft strength... Sounds paradoxical, doesn’t it? Commonly we perceive something as being strong, when it is hard, tough and rigid. But never soft.

Why can’t the engine bearings be just strong?

Is it not enough for their durable and reliable functioning?

The answer to the last question would be positive but only under one condition: if the engine bearings were ideal hydrodynamic bearings.

Unfortunately such ideal condition is unachievable in the real engines.

to top

Hydrodynamic bearing

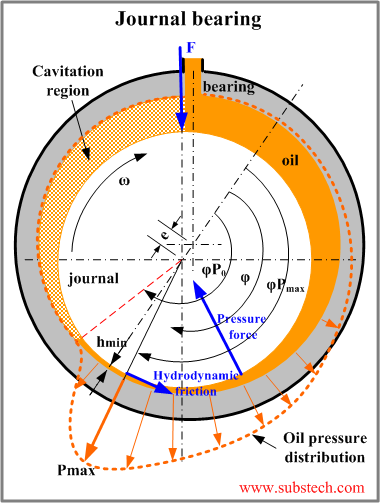

Hydrodynamic journal bearing is a bearing operating with hydrodynamic lubrication, in which the bearing surface is separated from the journal surface by pressurized oil (Fig.1).

Fig.1 Hydrodynamic journal bearing

A loaded rotating journal is always displaced from the concentric position, forming a converging gap (wedge) between the bearing and the journal surfaces. The presence of this oil wedge is indispensable to the normal operation of a hydrodynamic bearing.

Journal rotation causes pumping of lubricant (oil) flowing around the bearing in the rotation direction.The pumping action of the journal forces oil to squeeze through the wedge shaped gap generating pressure. The force created by oil pressure (pressure force) counteracts the external force F therefore the film separating the bearing and the journal surfaces remains stable. The film thickness is determined by the values of F, rotation speed, oil viscosity, oil clearance [2] and the geometric parameters of the bearing (diameter and length).

It is presumed that the ideal hydrodynamic bearing is absolutely rigid (as well as its housing), its axis is parallel to the journal axis, the journal has a shape of a perfect cylinder, the surfaces of the bearing and the journal are perfectly smooth, the oil supplied to the bearing is pure and its amount is sufficient for hydrodynamic lubrication.

The internal combustion engines are characterized by cycling loading of the bearings caused by alternating pressure of combustion gases in the cylinders and inertia forces developed by accelerating parts. Oscillating loads applied to a part may cause bearing failure as a result of the material fatigue. The lubricant (oil) film prevents localized overloading providing a distribution of the applied force over a relatively wide area. However If the pressure transmitted by the oil film to the bearing is greater than the fatigue strength of the material fatigue cracks form on the bearing surface. Thus sufficient fatigue strength is the only material property required for the ideal hydrodynamic bearing.

to top

Real bearing

Unfortunately the real engine bearings differ from the ideal journal bearing.

- The bearings are not absolutely rigid. The forces applied to the bearings distort their housings [3]. High performance engines commonly operate at high rotation speeds, which considerably increase the inertia forces generated by the accelerating/decelerating engine parts (e.g. the assembly of a piston with the connecting rod). In reaction to these inertia forces, the connecting rod and its bore are stretched in a vertical direction. The crankcase bores may also change their shape as a result of high loads applied to the main bearings. Under such conditions the oil wedge may change its shape from converging to diverging that deteriorates hydrodynamic lubrication and may cause direct friction between the journal and the bearing surfaces.

- A bearing is not always parallel to the journal. In addition the main bearing bores in a crankcase may be not aligned (concentric). Misalignments (deviations from concentricity) and non-parallelism cause direct contact between the bearing and the journal.

- The actual journal shape may deviate from the perfect cylinder [4]. If the journal pin diameter varies in the axial direction the journal shape forms one of the following patterns: taper (conical), barrel (convex) or hour glass (concave). Variations of the journal diameter in the tangential direction produce roundness defects: ovality or waves along the circumference of the journal (grinding chatter marks). Real journals may also change its shape as a result of bending caused by high normal or torsional torques which are characteristic for performance bearings. A non-cylindrical journal produces undesirable shape of the oil gap breaking the oil film between the bearing and journal surfaces.

- The journal and the bearing surfaces are not perfectly smooth. Direct metal-to-metal contact may also be caused by the surface roughness. Surface quality is particularly important in the racing bearings operating with low oil film thickness.

- Oil working in real environment always contains some impurities and contamination. Hard particles transported in the oil may trap between the rubbing surfaces causing direct friction and accelerated wear of the bearing material.

- Oil flows out of the bearing and returns to the oil sump. The leakage is compensated by oil supplied from the oil pump. If the side leakage is close to or greater than the pump capacity, the amount of oil becomes insufficient for generating a stable hydrodynamic film. Consequently, bearing lubrication turns to the mixed regime, characterized by a metal-to-metal contact between the bearing and journal surfaces. Such conditions are called oil starvation.

Thus the real engine bearings operate in a mixed regime of lubrication [5] characterized by intermittent contacts between the friction surfaces.

In contrast to the ideal hydrodynamic regime the bearings operating in a mixed lubrication should have a combination of the material properties including those attributed with softness.

to top

Properties of bearing materials

The real racing bearings work under conditions of great alternating loads, high rotation speeds, and intermittent metal-to-metal contacts with the journals and in the presence of impurities transported in the oil.

Here are the main properties of materials for engine bearings:

- Load capacity (fatigue strength) is the maximum value of cycling stress a bearing can withstand without developing Fatigue cracks after an infinite number of cycles.

- Wear resistance is the ability of the bearing material to maintain its dimensional stability (oil clearance) under conditions of mixed lubrication regime and in the presence of foreign particles carried by the lubricant.

- Compatibility (seizure resistance) is the ability of the bearing material to resist physical joining with the crankshaft journal when it contacts the bearing surface.

- Conformability is the ability of the bearing material to accommodate geometry imperfections of the journal, housing or bearing itself.

- Embedability is the ability of the bearing material to absorb small foreign particles transported in the lubricating oil.

- Corrosion resistance is the ability of the bearing material to resist chemical attack from the lubricant or substances that may enter and contaminate the lubricant.

- Cavitation resistance is the ability of the bearing material to withstand impact stresses caused by collapsing cavitation bubbles, which form as a result of sharp and localized drops of pressure in the circulating lubricant.

Fatigue strength, wear resistance and cavitation resistance characterize the material strength and hardness. Whereas compatibility, conformability and embedability are attributed to the material softness. The engine bearings should combine strength and softness. Common sense tells us that this is not possible since one characteristic (strength) contradicts the other (softness).

to top

Structures of bearing materials

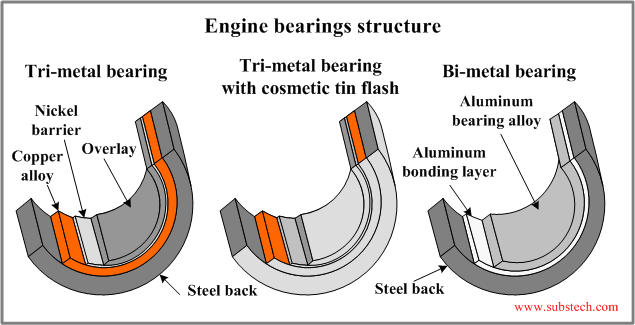

The contradictory combination of strength and softness may be achieved if the bearing material has a composite structure. Engine bearings are composed of a steel back, onto which is applied a relatively strong base (copper or aluminum) combined with a solid lubricant in the form of either a thin overlay or small particles distributed throughout the base material.

Bearing material having a thin overlay is called tri-metal, in contrast to materials without any overlay – bi-metal. Typical tri-metal and bi-metal engine bearing construction is shown in Fig. 2:

Fig. 2 Structures of bearing materials

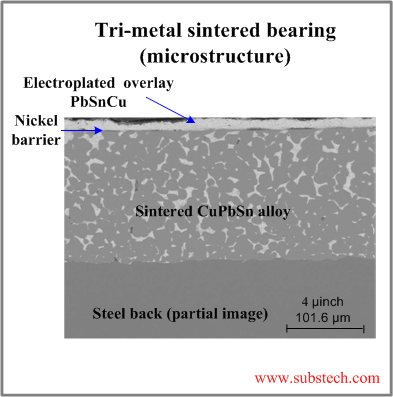

Microstructure of a typical tri-metal bearing is depicted in Fig. 3:

Fig. 3 Microstructure of a tri-metal bearing

The overlay provides softness of the bearing. Soft leaded alloys commonly used as the overlay material in racing bearings have excellent conformability, embedability and compatibility. The strength is provided by the intermediate layer made of a leaded bronze. Lead is added into the bronze composition in order to improve its compatibility (seizure resistance).

Tri-metal bearings have a limitation with regards to the thickness of the overlay. Overlay thickness is always the result of a compromise between the required load capacity and the bearing’s anti-friction properties. If the overlay is partially worn off this increases the threat of seizure between the crankshaft journal and the exposed bronze of the intermediate layer.

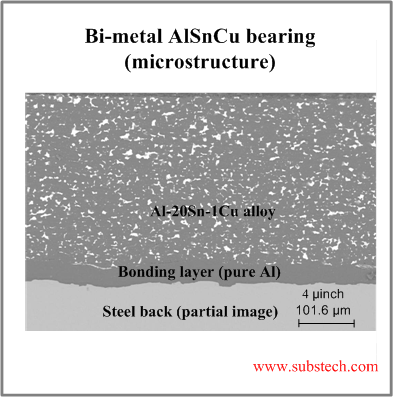

Bi-metal bearings do not have overlays therefore they are much more tolerant to the amount of wear. Fig. 4 depicts a typical microstructure of a bi-metal bearing.

Fig. 4 Microstructure of a bi-metal bearing

Aluminum alloy of a bi-metal bearing contains tin particles distributed throughout the aluminum matrix. Soft tin serves as a solid lubricant. It improves the seizure resistance of aluminum. Aluminum alloys are commonly softer than bronzes in tri-metal bearings therefore they provide good conformability and embedability properties for the material. Thickness of aluminum alloy in a bi-metal bearing is about 0.012”. They are capable to conform to greater distortions and misalignments than tri-metal racing bearings having overlays with a thickness 0.0005”.

to top

pMax Black™: Strengthened Tri-metal Bearing Material

Tri-metal bearings with soft leaded overlays are traditionally popular in racing applications. However the engines efficiency and the output have been considerably increased for last years. The specific loads applied to the bearings have also increased. In addition to the greater loading there is a trend to use the motor oils with a reduced viscosity which lower the power losses caused by friction.

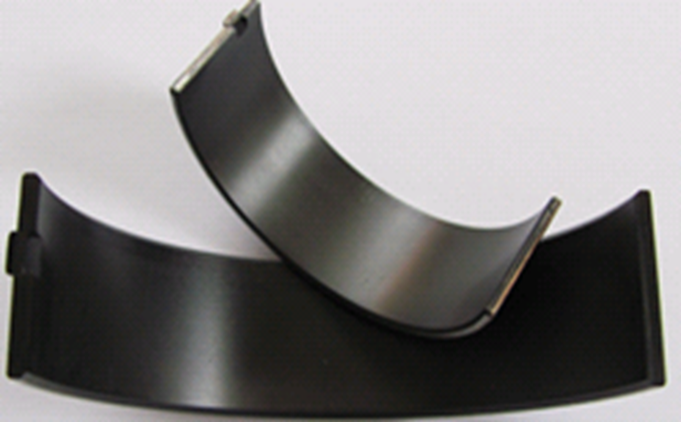

Thus the bearings in modern racing engines work at higher loads and lower minimum oil film thickness. The load capacity and wear resistance of traditional tri-metal materials may be insufficient for some high performance applications. King Engine Bearings has solved the problem with the strengthened tri-metal material pMax Black™ (Fig. 5) which has been developed for highly loaded racing engines.

This development comprises an innovative technique which enables the formation of an ultra-thin hardened shield on the overlay surface. This shield of nano-scale thickness considerably reduces wear of the overlay. It also effectively suppresses the formation of fatigue cracks on the overlay surface.

pMax Black™ bearings withstand greater loads without a formation of fatigue cracks and distress. The experiments using King’s test rig demonstrated that fatigue resistance of the pMax Black™ overlay is 10,200 psi. This is 17% greater than that of conventional tri-metal bearings (8700 psi).

At the same time, the properties of excellent seizure resistance, conformability and embedability – which are characteristics of soft overlays – are preserved. All King XP series high performance bearings are manufactured with this hardened pMax Black™ overlay. These bearings are easily recognizable by their distinctive dark color.

Fig. 5 King pMax Black™ bearings

It is important to emphasize that the overlay with the nano-scale hardened layer is still much softer than steel or cast iron. Therefore it produces no damage to the journal surface.

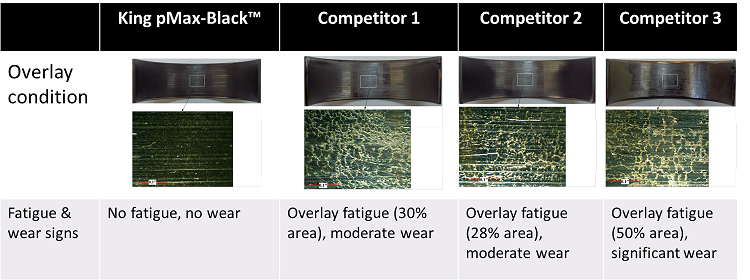

pMax Black™ bearings have been tested as compared to identical bearings made of conventional tri-metal material by four bearing manufacturers. The tests were performed in King Test Rig [6].

Test conditions: Load: 10,150 psi, Duration: 24 hrs.

The conditions of the bearings after the tests are depicted in Fig. 6.

Fig. 6 Fatigue test of King pMax Black™ vs. competitive materials

The bearing pMax Black™ has survived the test without overlay fatigue and any noticeable signs of wear.

Substantial area (between 28 to 50%) of the overlays on the competitive bearings has been affected with fatigue cracks and wear.

to top

Bi-metal racing HP bearings

Most of aluminum alloys used in bi-metal bearings have load capacity below 10,000 psi therefore they cannot be used in the engines combining high loads and relatively long service life. However some features of aluminum bi-metal bearings have clear advantages over tri-metal. First of all they do not have overlay. The working layer of a bi-metal bearing is relatively thick therefore bi-metal bearings are very tolerant to geometric defects of the housing and the journal and to the conditions of continuous metal-to-metal contact (characteristic for drag racing). The critical amount of wear in the bi-metal bearings is considerably greater than that in tri-metal bearings with thin overlay. King Engine Bearings has developed HP Bi-metal aluminum bearings. HP bearings are best suited for street/strip, all out drag racing, monster truck and medium loaded circle track racing engines. The aluminum alloy of HP bearings provides a balanced combination of good load capacity with good embedability and conformability - characteristics for absorbing debris and conforming to crankshaft deflection. \Compatibility of the alloy is additionally improved by the presence of silicon in the composition. Silicon helps to keep the ferrite cavities on the surface of the cast iron crankshaft rounded off to prevent seizure and excessive bearing wear.

to top

Conclusions

- In contrast to the Hydrodynamic journal bearing racing engine bearings work in the mixed regime of lubrication and with contaminated oil.

- Materials for engine bearings should combine strength with softness.

- A new tri-metal bearing material for high performance applications – pMax Black™ - has been developed by King Engine Bearings.

- It was proved that pMax Black™ bearings have the load capacity 17% greater than conventional tri-metal materials used for racing applications.

- Excellent seizure resistance, conformability and embedability, which are characteristics of soft overlays, are preserved.

- The hardened nano-scaled layer of pMax Black™ bearings produces no damage to the journal surface.

- Bi-metal material with silicon containing aluminum alloy has been developed by King Engine Bearings for medium loaded racing engines and for the engine bearings working in continuous metal-to-metal contact (drag racing, monster truck).

References

[1] Dudley D. Fuller (1958), A Survey of Journal Bearing Literature, Amer. Soc. of Lubricating Engineers

[2] Dmitri Kopeliovich, “Optimization of Clearance Design for High Performance Engine Bearings.” SubsTech (Substances & Technologies). Retrieved from www.substech.com/dokuwiki/doku. php?id=optimization_of_clearance_ design_for_high_performance_ engine_bearings.

[3] Dmitri Kopeliovich, “EccentriX™ Optimal Eccentricity for High Performance Bearings” SubsTech (Substances & Technologies). Retrieved from www.substech.com/dokuwiki/doku.php?id=eccentrix_optimal_eccentricity_for_high_performance_bearings

[4] Dmitri Kopeliovich, “Geometry and Dimensional Tolerances of Engine Bearings.” Engine Professional October-December 2011: 70-76.

[5] Dmitri Kopeliovich, “Lubrication regimes” SubsTech (Substances & Technologies). Retrieved from www.substech.com/dokuwiki/doku.php?id=lubrication_regimes

[6] Dmitri Kopeliovich, “Engine bearing fatigue test”, SubsTech (Substances&Technologies), Available from www.substech.com/dokuwiki/doku.php?id=engine_bearing_fatigue_test

to top

Related internal links

to Metals

to Engine bearings