Main page

About us

Sliding Bearings Consulting

Advertising Opportunities

SubsTech’s sister website Smooth Sliding provides independent engineering consulting services that help you to solve engine bearing related issues: failures, material selection, geometry design and optimization of hydrodynamic conditions.

Smooth Sliding is an engineering consulting company run by Dr. Dmitri Kopeliovich:

- VP R&D of King Engine Bearings.

- World leading expert (32 years of experience) in design, technology and materials for Engine bearings in applications such as automotive, renewable energy, aviation, racing and others.

- Founder and owner of SubsTech (Substances & Technologies) – a leading professional website on Materials Science and Engineering.

- Author of numerous scientific and engineering publications and patents.

- Founder and owner of Smooth Sliding.

For further information and for requesting consulting services please visit our sister website Smooth Sliding.

to Metals

to Engine bearings

Development of Performance Bearings for Race Engines of Modern Design

Engines and Engine Bearings

The first usable internal combustion engine was patented in 1860 by Belgian engineer Jean Joseph Etienne Lenoir. Its thermodynamic cycle was less effective than later engines invented by Otto and Diesel. The principal mechanical parts of all early engines were the same: a combustion cylinder, a piston, a connecting rod, a crankshaft, a flywheel and bearings (a couple of main bearings and a rod bearing). Mechanical energy from a rotating crankshaft was generated by the process of combustion of an air-fuel mixture taking place inside the cylinder. Gases formed as a result of combustion increased pressure in the cylinder. This pressure pushed the piston, performing linear reciprocating motion, through the cylinder. The piston and the eccentric crankpin journal of the crankshaft were linked by a connecting rod. The connecting rod enabled the reciprocating motion of the piston to be converted into rotating motion of the crankshaft. A connecting rod bearing assembly permitted rotating motion of the crankpin within the connecting rod. Two main crankshaft bearings supported the rotating crankshaft. The main bearings were mounted in the crankcase.

It is noteworthy that despite the great progress in engine design that has occurred in the last 150 years, the basic principle of thermodynamics and the basic mechanical structure of the internal combustion engine have not changed.

The invention and application of engine bearings actually predates the internal combustion engine. Engine bearings had been used in steam engines having the same principle of transforming reciprocating energy into rotating energy. From the beginning, engine bearings have been lubricated sliding bearings. In very early steam engines they were lubricated with tallow and later with oil. In automotive engines they are lubricated with motor oils and are referred to as hydrodynamic journal bearings. They operate with hydrodynamic lubrication, in which the bearing surface is separated from the journal surface by the lubricant film generated by journal rotation [1]. Pure hydrodynamic lubrication is an ideal condition that, unfortunately, is not achievable in real engines. Direct contact between the bearing and journal surfaces occurs intermittently. This metal-to-metal contact is not the only challenge faced by the bearings. Engine bearings experience load generated in the cylinder and transmitted by the connecting rod. Since the combustion process is cycling, the load is also cycling. Bearings operate under alternating mechanical stress which may cause material fatigue. The undesirable conditions of direct (non-hydrodynamic) friction and high alternating loads can have particular impact on race engines working at high rotation speeds and producing great specific power (power-to-displacement). Internal combustion engines are being continuously developed and improved. Race engines are on the cutting edge of such engineering trends. Racing has always served as the source, the stimulus and the testing ground for automotive engine enhancements.

The first Indy 500 race was held in 1911. The race was won by Ray Harroun with an average speed of 74.6 miles/hr [2]. His car (Stoddard-Dayton) had a 6-cylinder 50 HP engine with displacement 477 cu. in.. The power-to-displacement ratio was about 0.1 HP/cu. in. The modern Chevrolet Indy V6 engine displaces 134.3 cu. in. and makes 700 HP. Its power-to-displacement ratio is 5.2 HP/cu. in.. It is 52 times greater than that of the 1911 engine. The modern engine is 3.5 times smaller, but 14 times as powerful.

Such a great difference in engine performance requires very different bearings. In response to current developmental trends in race engine technology, this article will review the following specific areas that directly impact the design of high performance engine bearings with regard to their geometry, construction and materials:

- Load capacity of bearing materials sufficient to withstand cycling stresses without formation of fatigue cracks

- Anti-friction properties of bearing materials that reduce friction, prevent seizure and fast wear of the bearings

- Bearing geometry providing a stable hydrodynamic lubrication regime with minimal occurrence of metal-to-metal contact events

These aspects of bearing performance are considered with regard to the characteristics and parameters of modern racing engines.

to top

Volumetric Efficiency

Volumetric efficiency is the ratio of the volume of air-fuel mixture that enters the cylinder during the intake stroke compared to the cylinder’s volume.

The factors reducing volumetric efficiency are:

- Restrictions to air intake

- Restrictions to exhausting of gases

- Heating of the air-fuel mixture in the cylinders

At full power and wide-open throttle, volumetric efficiency of naturally aspirated engines reaches 80%.

Low volumetric efficiency decreases engine power output. In contrast, race engines are tuned to increase volumetric efficiency to even above 100%.

Methods of increasing volumetric efficiency are:

- Valve overlap. This is particularly effective in increasing volumetric efficiency of race engines working at high rotation speeds.

- Inertia charging. Kinetic energy of the airflow is used to increase the actual pressure in the cylinder greater than the atmospheric. Inertia charging is especially effective in high speed performance engines. Common methods are turbocharging and supercharging.

The volumetric efficiency of race engines may be increased up to 130%. This means the amount of energy generated in every combustion cycle of a modern race engine is nearly 50% greater than in engines for street use.

Greater combustion energy and higher air pressure produce greater combustion pressure. This pressure is transmitted by the connecting rod to the upper rod bearing and to the lower main bearings supporting the crankshaft. The bearings in engines with high volumetric efficiency work at greater alternating stresses. To withstand these stresses, stronger materials with higher load capacity are required.

to top

Turbocharging or Supercharging

Forced induction (turbocharging or supercharging) is the most effective method to increase engine power and torque. Boost pressure allows increasing the actual amount of air entering the cylinders. Correspondingly, the amount of fuel taken in and combusted in every cycle is also increased. As a result, the amount of horse power and torque are considerably greater than in naturally aspirated engines.

The first turbocharged engine to compete in the Indy 500 ran in 1966. It was able to produce 1,000 HP. Formula 1 cars have used turbocharged engines since 1977. Despite the fact that the maximum level of boost pressure is limited in some race venues, turbocharged race engines are common now. The maximum level of boost pressure (up to 70 psi) is achieved in Top Fuel dragsters with superchargers. In modern Formula 1 hybrid engines, boost pressure may reach 3.5 bar (51 psi). The pressures within the combustion chamber are up to 200 bar, which is 200 times as high as the atmospheric pressure, and 3 times as high as maximum pressure in normally aspirated engines.

Such extremely high combustion pressure is transmitted to the bearings and may cause fatigue of their materials. Additionally, high loads reduce oil film thickness to a level that leads to frequent intermittent contact of the bearing with the journal surface.

to top

Compression Ratio and Octane Number

Thermodynamic analysis of internal combustion engines shows clearly that engine efficiency is determined with the value of compression ratio. The same amount of fuel burned in one combustion cycle produces more HP output in an engine having higher compression ratio. Thus, for any concern (greater power, fuel economy, environment protection, cost) compression ratio should be as high as possible. This is especially important to high performance engines where extra HP output may be directly converted into better chances to win a race. However, the maximum level of compression ratio is limited by the possibility of detonation. Detonation is abnormally fast combustion of the charge. It produces extremely high peaks of pressure commonly called knocking. The fuel parameter controlling detonation is octane number. Race engines in the beginning of the 20th century had compression ratios of about 4:1. This is because until 1920 the octane number of gasoline was about 50. Modern performance engines using high octane fuels (above 100) containing methanol or ethanol may work without a risk of detonation at compression ratios that reach 15:1. With regard to bearings, the effect of high compression ratio is similar to that of forced induction (turbo or supercharging). A compressed air-fuel mixture produces higher pressure of the gases before combustion. In addition, the combustion process itself is more efficient. The gases heat up to higher temperatures which lead to higher pressures.

The pressure acts on the piston and it transfers the load via the connecting rod to the bearings. The upper rod bearing and the lower main bearings are then at risk of possible material fatigue and mixed regime of lubrication.

to top

Stroke-to-Bore Ratio

Engine displacement is determined by the piston stroke and the cylinder bore. At first glance, the amount of energy obtained in one combustion cycle is proportional to the mass of fuel (i.e. displacement). However, longer cylinders provide lower thermal loss due to lower area of heat transfer. So the engines with higher stroke-to-bore ratios are more efficient, they generate more mechanical power. In addition, longer cylinders possess better scavenging effect. In such cylinders, during valve overlap fresh air pushes the combusted gases out and doesn’t mix with them. So, in low speed engines, high stroke-to-bore ratio is preferable. Street use engines for cars and trucks have stroke-to-bore ratio in the range 1-1.5.

Race engines, however, should produce maximum power and therefore they work at very high rotation speeds. Indy car engines develop up to 12,000 RPM and modern Formula 1 engines are even faster – up to 18,000 RPM. At high rotation speed a significant part of the generated energy is consumed for acceleration and deceleration of engine parts (crankpin journals, piston, connecting rod). All those parts provide counteracting inertia forces which are proportional to the square of rotation speed. An increase of rotation speed as much as three times results in an increase of the inertia forces by a factor of 9. The first racing engines designed a hundred years ago worked at rotation speeds up to 2400 RPM. Their stroke-to-bore ratio was about 1.5. Shorter piston distances and lower eccentricity radius of the crankpin journal reduce inertia loading of modern high speed performance engines. The stroke-to-bore ratio of Indy 500 engines is about 0.7; of Formula 1 engines it is 0.4.

Stroke-to-bore ratio directly affects engine bearing operation. A decrease of the ratio means in fact an increase of the piston surface area and a corresponding increase of the force produced by the combustion pressure.

The force acts on the bearings, which need to withstand it without developing fatigue cracks. Also, the bearings should be capable of operating under conditions of very thin film of lubricating oil.

to top

Rotation Speed

At high speeds, which are a characteristic of race engines, the values of the inertia forces may be comparable to the value of the force generated by the combustion gases. However, the direction of the inertia force is opposite to those of the combustion force. It means that the summary force acting on the upper part of the rod bearing at high speed is lower than that at low speed. This effect plays a positive role since it reduces the risk of material fatigue of the upper bearing. It also improves hydrodynamic lubrication of the upper rod bearing. On the other hand, the lower rod bearing experiences a significant load resulting from the inertia forces. Under certain conditions the load acting on the lower rod bearing may be even greater than that acting on the upper. So the lower rod bearing material may potentially fatigue. The effect of the load caused by the inertia forces at high speed may also show up in the main bearings. In this case, the upper main bearings become loaded. The load effect is even more consequential for the main bearings since the effective area of the upper bearings is reduced by the oil groove and oil hole. Therefore the specific load applied to the upper main bearings is additionally increased.

to top

Oil Viscosity

Motor oil provides hydrodynamic lubrication, reduces friction and removes heat generated in the bearings. Oil viscosity index is a parameter for determining the value of hydrodynamic friction and also the value of the hydrodynamic lifting (separating) force counteracting the external force applied to the bearing from the crankshaft. The lifting force does not allow the journal surface to contact the bearing. More viscous oil provides a greater separating force that is stable even at relatively large oil clearances. High viscosity oil, however, generates greater hydrodynamic friction and this friction increases power losses. A race engine built to operate correctly with low viscosity oil will produce a higher mechanical power output. This is the main reason for the tendency to use low viscosity oils in modern high performance engines.

Unfortunately, the presence of high specific bearing loads coupled with the use of low viscosity motor oils may produce minimum oil film thicknesses that are below the surface roughness of the crank journals. These conditions create a mixed lubrication regime that allows.intermittent metal-to-metal contact between the journal and bearing surfaces. This can cause excessive wear and even seizure of the bearing with the journal. In order for a bearing to survive such circumstances, its anti-friction material must have the contradictory properties of high load capacity coupled with very good seizure and wear resistance.

to top

Diesel Racing Engines

Diesel engines are not popular in speed races, but they are used in endurance, truck and tractor pulling, boat and drag racing. Diesel engines are characterized by a high compression ratio (17…22). Therefore they have an advantage in thermal efficiency as compared to spark ignition engines (e.g. gasoline). Due to their high compression, combustion pressure in the cylinders of a diesel engine is very high and may reach 200-230 atmospheres.

Accordingly, the load applied to the bearings (particularly the upper rod bearings) is also very high. Special materials having high load capacity are required for such bearings.

to top

Hybrid Racing Engines

Hybrid engines are very new to racing applications. Currently they are mainly used in Formula 1, where the race regulations limit fuel flow to a maximum 100 kg/hour. As previously stated, stable hydrodynamic lubrication of a bearing is established when the journal’s rotation speed is sufficient for formation of a separating force equal to the external force. The major disadvantage of hybrid engines is that the condition of low rotation speed occurs frequently, every time the internal combustion engine shuts down and switches to the electric motor. Bearings working in a hybrid engine experience the condition of direct non-hydrodynamic friction very frequently. Therefore, the lubricating and anti-friction properties of the bearing surface are much more important than for bearings operating in non-hybrid engines.

Hybrid race engine applications require special wear resistant coatings containing solid lubricants and combining the properties of very high load capacity and excellent surface lubricity.

to top

Downsizing of Race Engines

It was noted in the introduction that in the past 100 years the power-to-displacement ratio of race engines has increased by a factor of 52. Modern engines make much more power, yet they are considerably smaller and lighter. So too are the crankshafts and their bearings. As a result, greater loads are applied over smaller bearing areas. Thus, specific loading of the bearings has significantly increased.

Small but powerful engines require bearing materials with high fatigue strength. Due to the increase in bearing loading, oil film thickness may be insufficient to prevent metal-to-metal contact between the bearing and journal surfaces. One more challenge emerging from the tendency to downsize engines and their components is insufficient rigidity of crankshafts and their housings.

Crankshafts bend under load. Their journal surfaces become non-parallel to the bearing surfaces. This causes local breaking of hydrodynamic lubrication and edge wear. Light weight design and engine block materials do not allow a firm press fit of the bearing inside its housing, which is crucial under high loads.

Bearing materials working under such conditions should have good conformability. This is the ability of the bearing material to accommodate geometry imperfections of the housing or journal.

to top

Conditions of Operation of Modern Engine Bearings

The effects of the different parameters of modern race engines on the conditions of bearing operation are as follows:

- High specific load applied to the bearing

- Very low values of minimum oil film thickness (40 µinch and lower)

- Mixed regime of lubrication with frequent metal-to-metal contact

- Non-parallelism of the rubbing surfaces as a result of elastic deformation of the crankshaft and housing

- Increased rotation speed

- Low viscosity and high working temperature of motor oils

Development of Modern Race Engine Bearings

King Engine Bearings realizes that the classic traditional bearing materials are not capable of withstanding the severe conditions produced by modern race engines. King undertakes research and development of bearings for racing applications in three major directions:

- Materials with high load capacity

- Coatings for operation in the regime of mixed lubrication

- Design features

Development of Materials with High Load Capacity

King Engine Bearings has developed the strengthened tri-metal material pMax Black™ [3]. This development comprises an innovative technique which enables the formation of an ultra-thin hardened shield on the overlay surface. Experiments using King’s test rig proved that the fatigue strength of the pMax Black™ overlay is 10,200 psi, which is 17% greater than that of conventional tri-metal bearings. At the same time, the properties of excellent seizure resistance, conformability and embedability – which are characteristics of soft overlays – are preserved.

These bearings are easily recognizable by their distinctive dark color.

Fig. 1 King pMax Black™ bearings

It is important to emphasize that the pMax Black™ overlay with its nano-scale hardened layer is still much softer than steel or cast iron. Therefore it produces no damage to the journal surface in the event of contact.

King Engine Bearings has developed HP Bi-metal aluminum-silicon-tin bearings. HP bearings are best suited for street/strip, all out drag racing, monster truck and medium loaded circle track racing engines. The aluminum alloy of HP bearings provides a balanced combination of good load capacity with good embedability and conformability - characteristics for absorbing debris and conforming to crankshaft deflection. Compatibility of the alloy is additionally improved by the presence of silicon in the composition. Silicon will remove and polish off any ferrite peaks that may be present on the journal surface of nodular cast iron crankshafts. This serves to prevent seizure and excessive bearing wear.

Development of Coatings for Operation in the Regime of Mixed Lubrication

Lack of liquid lubricant (oil) during mixed lubrication may be compensated by the presence of Solid lubricants distributed in the form of fine particles within a polymer matrix. The resulting material is then applied to serve as the top layer of the engine bearings. In addition to solid lubricants, polymer coatings developed by King Engine Bearings contain reinforcing phases in the form of nano-size particles that are dispersed throughout the polymer matrix. Similar to oil film, a polymer coating separates the metallic bearing material from the crankshaft surface.

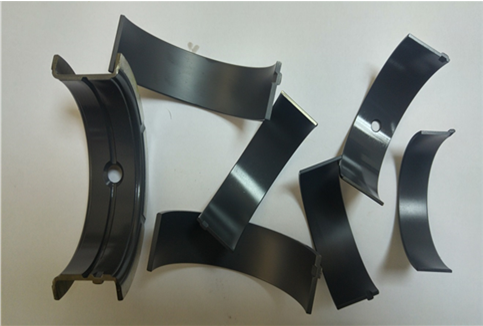

Fig.3 Polymer coated King race bearings

Three different types of polymer coatings for different applications have been developed by King Engine Bearings: K-340, K-334 and K-40.

K-340 is a strong coating, offering exceptional wear resistance, toughness and fatigue strength. It is able to operate under loads up to 17,400 psi.

K-334 is a wear resistant coating for applying over relatively soft substrate. K-334 was developed for coating tri-metal pMax Black™ XP high performance bearings. The coating helps to improve XP bearing wear resistance under conditions of metal-to-metal contact. It also increases resistance to cavitation erosion.

K-40 is a relatively soft coating. It is sacrificial by design, with excellent conformability and anti-friction properties. K-40 was designed specially for engines experiencing continuous metal-to-metal contact. This is characteristic of the extreme loading and conditions found in drag racing.

Development of Race Bearing Design Features

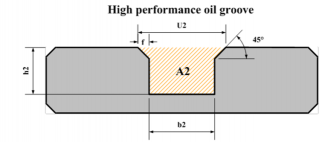

At high rotation speeds in high performance engines, the absolute loads applied to the upper and lower bearings may become close to each other. In this case the specific load (force per unit area) applied to the upper bearing may exceed the specific load to the lower bearing. U-Groove™ design of oil groove allows increasing the effective area of the upper main bearing. Such design results in reduction of the specific load applied to the bearing.

Fig.4 Oil groove design U-Groove™

A new design of oil hole was developed by King Engine Bearings for the upper shells of high performance main bearings. In the new design, the oil hole cross sectional area has been increased by the combination of a circular oil hole with a slot located in the oil groove. ElliptiX™ hole allows increasing oil passage capacity without reducing the effective bearing area.

Fig.5 Oil hole design ElliptiX™

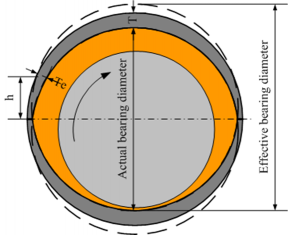

Bearing eccentricity (the difference between the maximum and minimum wall thickness) helps to establish stable hydrodynamic lubrication and enables creating and retaining the wedge shape of the oil gap, even in a distorted housing [4]. The high rotation speeds of race engines require a greater value of eccentricity for optimization and stabilization of hydrodynamic lubrication.

Fig.6 Optimal engine bearing eccentricity EccentriX™

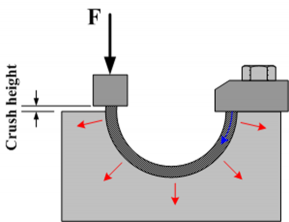

RadiaLock ™ design ensures optimal crush height values, and perfect radial pressure. This is particularly important in racing applications where determining the correct amount of crush height is critical.

Fig.7 Optimal crush height design RadiaLock ™

to top

Conclusions

The following trends in modern race engine design challenge the manufacturers of race engine bearings:

- Volumetric efficiency

- Turbocharging and supercharging

- Compression ratio and octane number

- Stroke-to-bore ratio

- Rotation speed

- Oil viscosity

- Diesel racing engines

- Hybrid racing engines

- Downsizing of racing engines

It was shown that bearings in modern race engines should withstand greater alternating loads and be capable to work in a mixed regime of lubrication.

Innovative bearing materials (pMax Black™ and HP), polymer coatings: K-340, K-334 (pMax Kote™), K-40 and newly developed design features (U-Groove™, ElliptiX™, EccentriX™, RadiaLock ™) meet the extreme demands of modern race engines.

to top

14. References

[1] Dmitri Kopeliovich, “Lubrication regimes” SubsTech (Substances & Technologies). Retrieved from www.substech.com/dokuwiki/doku.php?id=lubrication_regimes

[2] “Indianapolis 500 automobile race” Encyclopædia Britannica. Retrieved from https://www.britannica.com/sports/Indianapolis-500

[3] Dmitri Kopeliovich, “Bearing Materials for Race Engines” SubsTech (Substances & Technologies). Retrieved from http://www.substech.com/dokuwiki/doku.php?id=bearing_materials_for_race_engines

[4] Dmitri Kopeliovich, “EccentriX™ Optimal Eccentricity for High Performance Bearings” SubsTech (Substances & Technologies). Retrieved from www.substech.com/dokuwiki/doku.php?id=eccentrix_optimal_eccentricity_for_high_performance_bearings

to top

Related internal links

to Metals

to Engine bearings