SubsTech’s sister website Smooth Sliding provides independent engineering consulting services that help you to solve engine bearing related issues: failures, material selection, geometry design and optimization of hydrodynamic conditions.

Smooth Sliding is an engineering consulting company run by Dr. Dmitri Kopeliovich:

- VP R&D of King Engine Bearings.

- World leading expert (32 years of experience) in design, technology and materials for Engine bearings in applications such as automotive, renewable energy, aviation, racing and others.

- Founder and owner of SubsTech (Substances & Technologies) – a leading professional website on Materials Science and Engineering.

- Author of numerous scientific and engineering publications and patents.

- Founder and owner of Smooth Sliding.

For further information and for requesting consulting services please visit our sister website Smooth Sliding.

to Metals

to Engine bearings

Copper based bearing materials

Dr. Dmitri Kopeliovich

The design of internal combustion engines has a tendency of decreasing the engine dimensions. This tendency leads to more compact bearings and consequently to higher specific alternating loads applied to them.

Copper based Engine bearing materials provide superior fatigue strength (load capacity).

Copper based bearing alloys commonly contain tin (up to 10%) as a strengthening component and a soft component (lead or bismuth) distributed in a copper-tin matrix as a separate phase in form of small particles.

Soft component imparts to the material anti-friction properties (compatibility, conformability, embedability).

Maximum content of soft phase is about 25%.

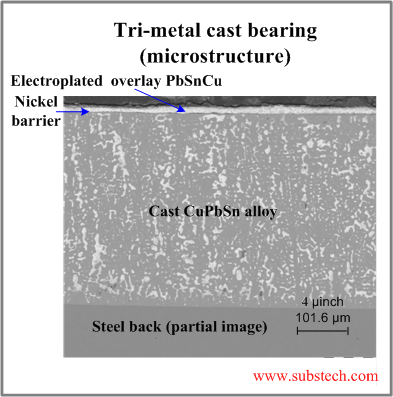

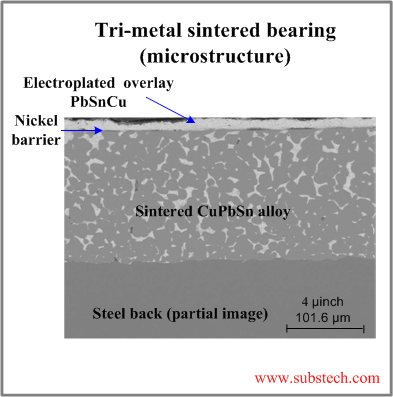

Copper based bearing alloys are manufactured by either casting or sintering technology.

Despite the presence of soft components in most copper based bearing alloys their anti-friction properties are poor therefore copper (bronze) bearings are rarely used in engines in monometal (solid) or bi-metal (steel backed) forms.

Typical copper bearings are steel backed and overplated with a thin sliding layer (overlay) of a soft material (tri-metal structure). The overlay improves the anti-friction properties of the copper alloy.

Modern copper based bearing alloys do not contain lead because of its harmful effect on the environment. Lead in lead free alloys may be substituted by harmless bismuth having excellent anti-friction properties comparable with lead.

Load carrying capacity of copper based bearings is determined by the fatigue strength of the overlays:

- Lead based overlays: 7250-10150 psi (50-70 MPa)

- Tin based overlays: 11600-13000 psi (80-90 MPa)

- Sputter overlays: 14500-17400 psi (100-120 MPa)

Characteristics of some copper based engine bearing materials

| Composition | Technology | Structure | Hardness, HV | Diffusion barrier | Overlay | Applications |

|---|---|---|---|---|---|---|

| CuPb25Sn1 | Cast | Tri-metal | 55 | Nickel | Pb10Sn2Cu | Low loaded bearings |

| CuPb23Sn1.5 | Cast | Tri-metal | 60 | Nickel | Al20Sn sputter | Highly loaded conrod bearings |

| CuPb23Sn1.5 | Cast | Tri-metal | 60 | no or Nickel | Pb10Sn12In | Medium and highly loaded bearings |

| Cu24Pb243.5Sn | Cast | Multilayer | 65 | Nickel | Pb10S3Cu + MoS2 in resin | Racing car engine bearings |

| Cu20Pb3Sn | Cast | Tri-metal | 65 | Nickel | Pb10Sn3Cu | Medium loaded bearings |

| Cu15Pb7Sn | Cast | Bi-metal | 80 | no | no | Small end bushes |

| Cu15Pb7Sn | Cast | Solid | 80 | no | no | Thrust washers |

| Cu10Pb10Sn | Cast | Bi-metal | 100 | no | no | Highly loaded Small end bushes |

| Cu10Pb10Sn | Cast | Solid | 100 | no | no | Highly loaded Small end bushes |

| Cu8Al | Cast | Solid | 145 | no | no | Highly loaded bushes, lead free |

| Cu24Pb1Sn | Sintered | Tri-metal | 55 | Nickel | Pb10Sn2Cu | Low loaded bearings |

| Cu5Sn1Ag | Sintered | Tri-metal | 80 | no | MoS2 in resin | Medium loaded bearings, lead free |

| Cu22Pb1Sn | Sintered | Multilayer | 55 | Nickel | NiSn + SnCu | Medium and highly loaded bearings |

| Cu24Pb3.5Sn | Sintered | Tri-metal | 65 | Nickel | Pb10Sn3Cu | Medium loaded bearings |

| Cu20Pb4.5Sn | Sintered | Tri-metal | 70 | Nickel | Pb10Sn5Cu | Medium and highly loaded bearings |

| Cu10Pb10Sn | Sintered | Bi-metal | 100 | no | no | Highly loaded Small end bushes |

| Cu3Bi10Sn | Sintered | Bi-metal | 130 | no | no | Highly loaded bushes, lead free |

Related internal links

to Metals

to Engine bearings