SubsTech’s sister website Smooth Sliding provides independent engineering consulting services that help you to solve engine bearing related issues: failures, material selection, geometry design and optimization of hydrodynamic conditions.

Smooth Sliding is an engineering consulting company run by Dr. Dmitri Kopeliovich:

- VP R&D of King Engine Bearings.

- World leading expert (32 years of experience) in design, technology and materials for Engine bearings in applications such as automotive, renewable energy, aviation, racing and others.

- Founder and owner of SubsTech (Substances & Technologies) – a leading professional website on Materials Science and Engineering.

- Author of numerous scientific and engineering publications and patents.

- Founder and owner of Smooth Sliding.

For further information and for requesting consulting services please visit our sister website Smooth Sliding.

to Metals

to Engine bearings

Engine bearing fatigue test

Dr. Dmitri Kopeliovich

The internal combustion engines are characterized by cycling loading of the bearings caused by alternating pressure of combustion gases in the cylinders and inertia forces developed by accelerating parts.

Oscillating loads applied to a part may cause Engine bearing failure as a result of the material Fatigue. This occurs if the load exceeds the fatigue strength (load capacity): the maximum value of cycling stress that the bearing can withstand after an infinite number of cycles.

Engine bearings are referred to hydrodynamic journal bearings operating with hydrodynamic lubrication, in which the bearing surface is separated from the journal surface by the lubricant film generated by the journal rotation. The lubricant (oil) film prevents localized overloading providing a distribution of the applied force over a relatively wide area.

If the pressure transmitted by the oil film to the bearing is higher than the fatigue strength of the material fatigue cracks form on the bearing surface spreading towards the back layer and may result in peeling off the Engine bearing materials.

Fatigue strength (load capacity) is one of the most important Requirements to engine bearing materials.

When bearing materials are selected for a particular engine the loads applied to the bearings (calculated or measured) are compared to the fatigue strength of the bearing materials.

The fatigue strength values of different engine bearing materials under controllable conditions (oil temperature, rotation speed, shaft roughness, loading character) are evaluated in fatigue test rigs simulating operation of the bearings in real engines.

The following types of fatigue test rigs are used by the engine bearings manufacturers:

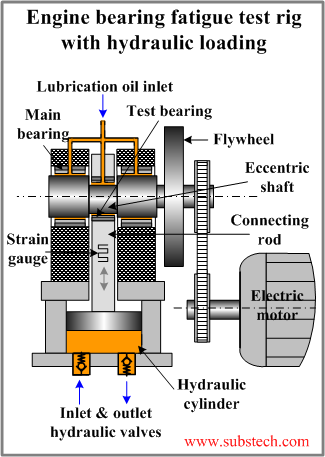

Fatigue test rig with hydraulic loading

The principle of this type of Fatigue test machine is similar to internal combustion engines, in which pressure generated in the cylinders is transmitted to the bearings through the connecting rod.

The test rig uses an eccentric shaft located between two concentric shaft parts. The eccentricity is small therefore the inertia forces generated by moving parts are negligible.

The test bearing coupled with the eccentric shaft is mounted in the big end of the connecting rod. Rotation of the eccentric shaft results in reciprocating motion of the connecting rod.

The shaft is supported by two main bearings operating against the concentric shaft parts. The main bearings provide the shaft rotation under oscillating forces transmitted by the connecting rod.

The shaft is driven by an electric motor. The rotation speed of the test rig is within the range 3000-5000 RPM.

Hydrodynamic lubrication is provided by oil supplied to the bearings through the holes in the housings and the upper parts of the bearings.

The small end of the connecting rod is connected to the hydraulic cylinder piston, which performs reciprocating motion together with the rod.

When the connecting rod goes up the cylinder volume increases and oil fills it through the inlet valve. At this phase the oil pressure determined by the oil pump is relatively low. The outlet valve adjusted to the opening at the peak test pressure is closed.

The piston reaches the upper position and starts to move down forcing the oil in the cylinder to flow through the outlet valve. The oil pressure at this phase is high. The inlet valve is closed since the pressure of the pump is lower than the cylinder pressure. The load generated in the cylinder is transmitted by the connecting rod to the lower part of the test bearing.

The adjustable opening pressure of the outlet valve determines the load applied to the test bearing. The precise value of the load is measured by strain gauges mounted on the connecting rod.

to top

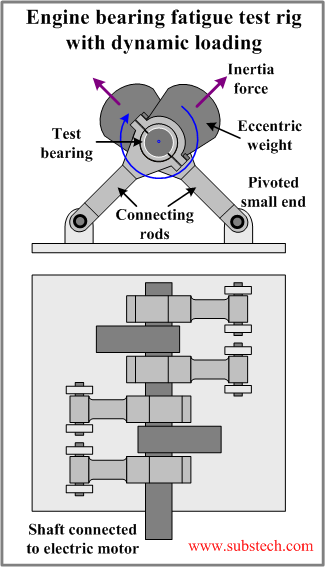

Fatigue test rig with dynamic loading

The principle of this type of Fatigue test rig is based on inertia forces generated by out-of-balance shaft.

The structure is similar to that of crankshaft of internal combustion engines with crank pins, counter weights and webs located off-center on the shaft.

The out-of-balance conditions of the test rig are achieved by off-center weights mounted on the shaft.

The test bearings are mounted in the big ends of connecting rods. The small ends are pivoted to the rig base.

The shaft is driven by an electric motor.

Hydrodynamic lubrication is provided by oil supplied to the bearings.

The inertia (centrifugal) force generated by a out-of-balance weight is determined by its mass M, angular speed ω and the distance between the shaft axis and the mass center R:

F = Mω2R

or

F = M(120π/N)2R

where N is rotation speed, RPM

The loads applied to the test bearings are resulted from the vector sum of the inertia forces.

to top

Related internal links

to Metals

to Engine bearings